Steel structure design

There are three different methods in the design of steel structures: simple design, continuous design and semi-continuous steel construction design.

- Home

- Our-services

- Steel structure design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

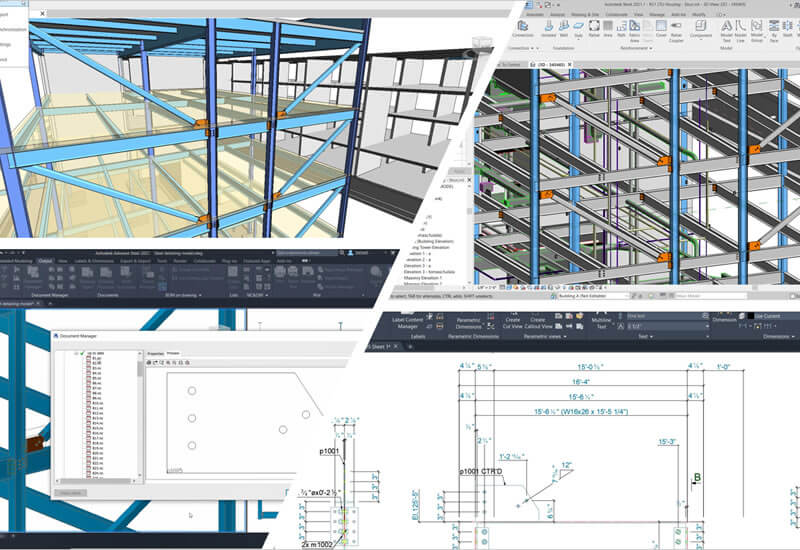

Steel structure design

Steel structures are often preferred in projects that require complex skeletal systems and the ability to withstand large forces. In addition, such structures require large spans and it is important that they are flexible structures that can be easily assembled and disassembled.

In steel structures, joints are assumed to behave as fixed or rigid in order to make design calculations manageable. In simple design, joints are idealized as perfect pins. Continuous design assumes that joints are rigid and that no relative rotation occurs in the connected members regardless of the applied moment. The vast majority of designs conducted today make one of these two assumptions, but a more realistic alternative known as semi-continuous design is now possible.

When the mixed gas enters the system from the middle section of the washing tower, the liquid product component between the trays and the vaporized part of the product component gas simultaneously liquefies. However, impurities do not become liquid or solidify. As the gas passes through the liquid component trays, the liquid product component is fixed and thus an effective washing effect occurs. The design and production of the washing tower was carried out based on this principle.

Steel Structure Design Methods

- ✓ 1 Simple Steel Structure Design

Simple Steel Structure Design is the most traditional approach and is still widely used. It is assumed that no moments are transmitted from one connected member to another, except for nominal moments resulting from eccentricity at the joints. The resistance of the structure to lateral loads and sway is usually provided by the provision of supports or, in some multi-storey buildings, by concrete cores. It is important for the designer to recognise the assumptions regarding joint response and to ensure that the detailing of the connections is such that no moments are generated which could adversely affect the performance of the structure.

Years of experience have shown the types of detail which meet this criterion and the designer should resort to standard connections at joints in simple construction.

- ✓ 2. Continuous Design of Steel Structure

In continuous design, the joints are assumed to be rigid and moments are transferred between the members. The stability of the frame against sway is provided by the frame motion (i.e. bending of beams and columns). Since continuous design is more complex than simple design, software is commonly used to analyze the frame.

Realistic combinations of pattern loading should be considered when designing continuous frames. The connections between members should have different properties depending on whether the frame is designed as elastic or plastic. In elastic design, the joints must have sufficient rotational stiffness to ensure that the force and moment distribution around the frame does not differ significantly from those calculated.The joint must be able to carry the moments, forces, and shears resulting from the frame analysis.

In plastic design, the strength of the joint (not its stiffness) is of primary importance in determining the ultimate load capacity. The strength of the joint will determine whether plastic hinges will form at the joints or in the members and will have a significant effect on the collapse mechanism. If the joints are designed to have hinges, the joints must be detailed with sufficient ductility to accommodate the resulting rotations. The stiffness of the connections will be important when calculating beam deflections, swing deflections and rocking stability.

- ✓ 3. Semi-Continuous Design of Steel Structure

True semi-continuous design is more complex than simple or continuous design, as the actual joint response is more realistically represented. Analytical routines for closely following the actual connection behaviour are quite complex and require the use of complex computer programs, and are therefore not suitable for routine design.

However, two simplified procedures are available for both braced and unbraced frames; these are briefly discussed below. Braced frames are frames in which the resistance to lateral loads is provided by a system of braces or a core; in unbraced frames this resistance is produced by bending moments in columns and beams. The simplified procedures are as follows. Wind moment method for unbraced frames. In this procedure, the beam/column joints are assumed to be fixed when considering vertical loads. However, under wind loading they are assumed to be rigid, meaning that the lateral loads are carried by the frame movement.

A more complete description of the method can be found in Reference Semi-continuous design of braced frames. In this procedure, actual joint behaviour is taken into account to reduce the bending moments and deflections applied to the beams. Details of the method can be found in Reference.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.