Pressure vessel design

Pressure vessel design, as a type of unit, is one of the most important components of industrial and petrochemical process plants.

- Home

- Our-services

- Pressure vessel design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

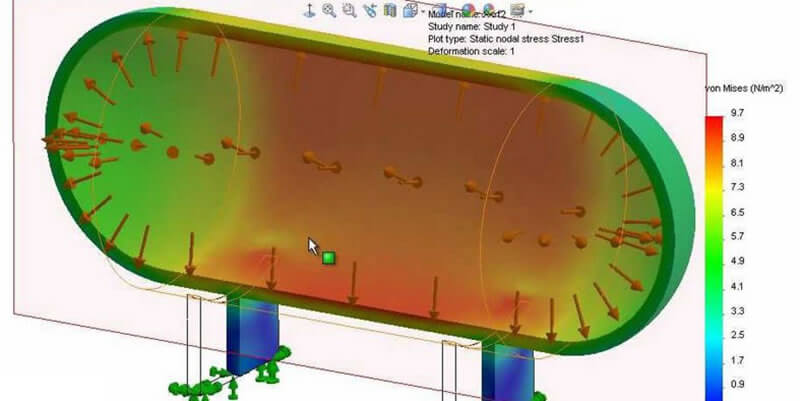

Pressure vessel design

In a broad sense, the term pressure vessel covers a wide range of unit heat exchangers, reactors, storage vessels, columns, separation vessels, etc. (See also Mechanical Design of Heat Exchangers.) Due to the risks associated with any pressure, such as the accidental release of the contents, the manufacture and operation of pressure vessels is regulated in many countries. This legislation may define the national standard to which the pressure vessel is to be designed, the inclusion of independent inspection during construction, and subsequent regular inspection and testing during operation. Some national pressure vessel standards, such as ASME VIII (1993) or BS5500 (1994), have de facto international standard status.

National legislation and/or standards usually define when a vessel is considered a pressure vessel. A minimum pressure definition (typically 5,104 N/m2) will exclude low-pressure vessels and a minimum of a few litres, piping and pipework components. Note that vessels operating in vacuum are usually defined as pressure vessels to ensure that the design, construction, etc. are of acceptable quality.

For design and construction purposes, a pressure vessel is generally defined as a pressure vessel that includes welded connections up to and including the nozzle flanges, screw or welded connectors, or connecting pipes and the edges to be welded in the first circumferential weld.

The most commonly used and preferred form of pressure vessel design is the two-headed cylindrical shape known as a “headed cylinder” or “end-cap cylinder”. This design is very popular due to its practicality and cost-effectiveness over spherical vessels. Although economical, cylindrical vessels are generally weaker in construction than spherical ones and generally require thicker walls to provide similar strength under the same internal pressure.

Pressure Vessels are commonly used in the Oil and Gas, Chemical Manufacturing and Processing, Food and Beverage, Pharmaceutical and Aerospace industries.

In pressure vessel design

The design of pressure vessels is done according to standards defined by ASME codes. These codes provide guidance for the design, construction, maintenance, and inspection of pressure vessels and ensure that they meet safety and performance requirements. Various ASME codes, such as VIII-1, specify rules and formula methods that must be followed for effective and compliant pressure vessel design.

- 1 ASME Section VIII for Ships, Towers, and Exchangers

A standard that deals with the design and construction of pressure vessels, particularly towers and heat exchangers. This code provides guidance on how to safely design, manufacture and inspect such equipment to ensure its reliability and safety under a variety of conditions. See ASME Code Section VIII

- 2-ASME Section I and IV for Boilers and Hot Water Heaters

Covers the design, construction, and maintenance of boilers and water heaters. Part I focuses on rules for ensuring the safe operation of power boilers, while Part IV provides standards for heating boilers, emphasizing the safety and efficiency of hot water heating systems. See ASME Code Parts I and IV

- 3- ASME B31.1, B31.3 and B31.5 for Piping Systems

The ASME B31 standard is specifically tailored to different piping systems.

ASME B31.1 provides guidance for the design, construction, and maintenance of energy piping systems in power plants and industrial facilities.

ASME B31.3 focuses on process piping systems, ensuring the safety and reliability of pipelines in a variety of industries.

B31.5 provides standards for the design, construction, and maintenance of piping systems in refrigeration applications.

ASME B31.3 applies to many fittings as well as process piping systems.

This expansion ensures that the design and use of fittings such as elbows, tees, and valves are consistent with the standards, maintaining consistency and safety in the overall piping system.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.