Gas scrubber tower design

Gas scrubber tower design makes it more critical than ever to maintain an efficient operation at your facility.

- Home

- Our-services

- Gas scrubber tower design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

Gas scrubber tower design

Not only are we dealing with an energy crisis, but we are also facing increasingly stringent emissions regulations. Fortunately, energy savings, cost savings, sustainability, and regulatory compliance can go hand in hand.

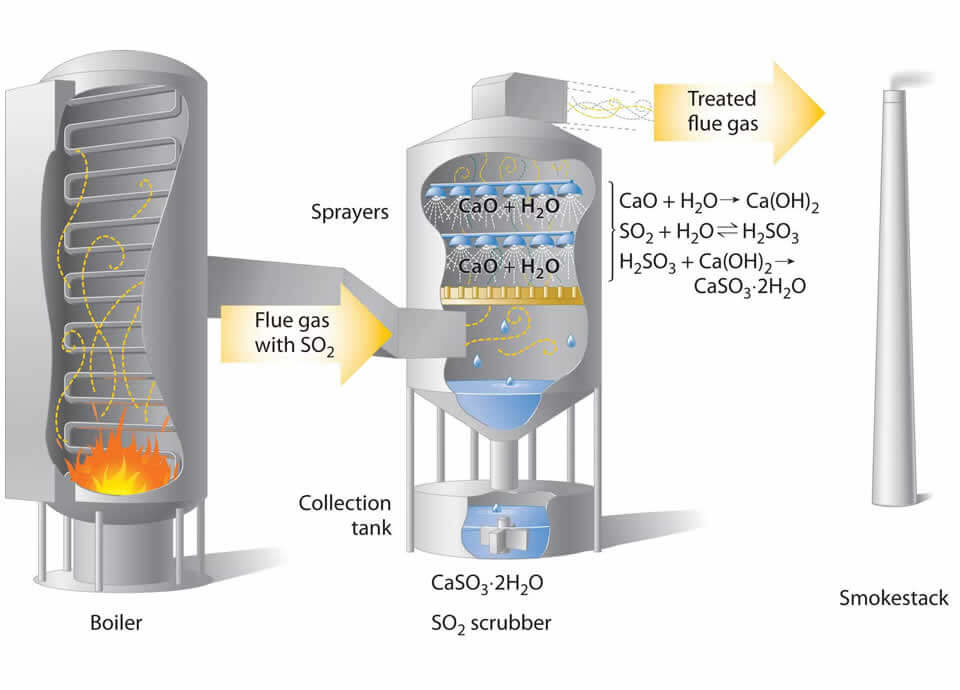

The scrubber design with Energy Recovery Scrubber effectively cleans your exhaust streams, reducing unwanted emissions to the environment. In addition, the scrubber design removes heat from the same exhaust stream, which can be reused in your facility.

Industrial processes often produce exhaust streams that contain unwanted byproducts and contaminants. In many cases, untreated exhaust streams can be harmful to the environment and human health.

Industrial scrubbers effectively remove contaminants from the exhaust stream. Inside the scrubber, the exhaust stream comes into contact with liquid droplets (e.g. water or other solvent) in which the unwanted substances are dissolved. As a result, the exhaust stream is freed of harmful gases, particles, solids, and fumes. After this treatment, the exhaust stream can be safely released into the environment.

How does a scrubber tower recover energy?

During the scrubbing process, the scrubbing fluid not only captures contaminants or vapors, but also absorbs heat. Inline Venturi Scrubbers can therefore also function as heat recovery equipment, especially if the exhaust stream has a relatively high temperature. Reducing the temperature of the exhaust stream during the scrubbing process will also increase the absorption of vapors into the scrubbing fluid.

The heat captured by the scrubbing fluid can be recovered using a heat exchanger. This heat can then be reused by other consumers within or outside the facility, allowing the facility to be operated more economically. Our Energy Recovery Scrubbers are often used to save on heating services in offices, factories and other process equipment, especially where hot water is in demand.

The recovered heat can be further processed with additional equipment, depending on specific needs, such as:

✓ Heat pumps

✓ Absorption chillers

✓ Low-temperature electrical generators

✓ Thermal energy storage systems

With an intelligent automation system, the Energy Recovery Scrubber adapts to the factory operating conditions while requiring minimal interaction from operators.

✓ Heat pumps

✓ Absorption chillers

✓ Low-temperature electrical generators

✓ Thermal energy storage systems

With an intelligent automation system, the Energy Recovery Scrubber adapts to the factory operating conditions while requiring minimal interaction from operators.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.