Crusher design

It is widely used as the primary stage in crusher design to produce particulate product whose size is finer than about 50-100 mm.

- Home

- Our-services

- Crusher design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

Crusher design

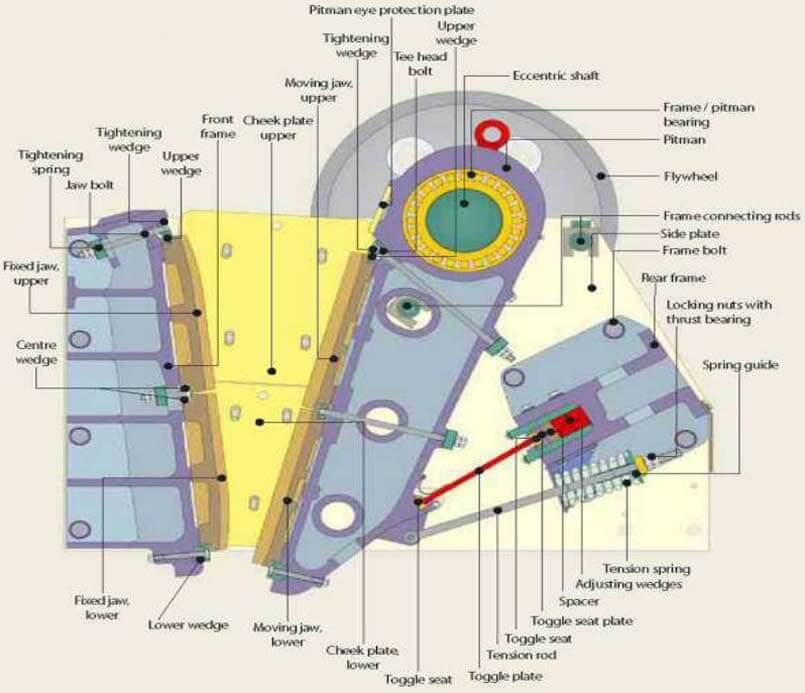

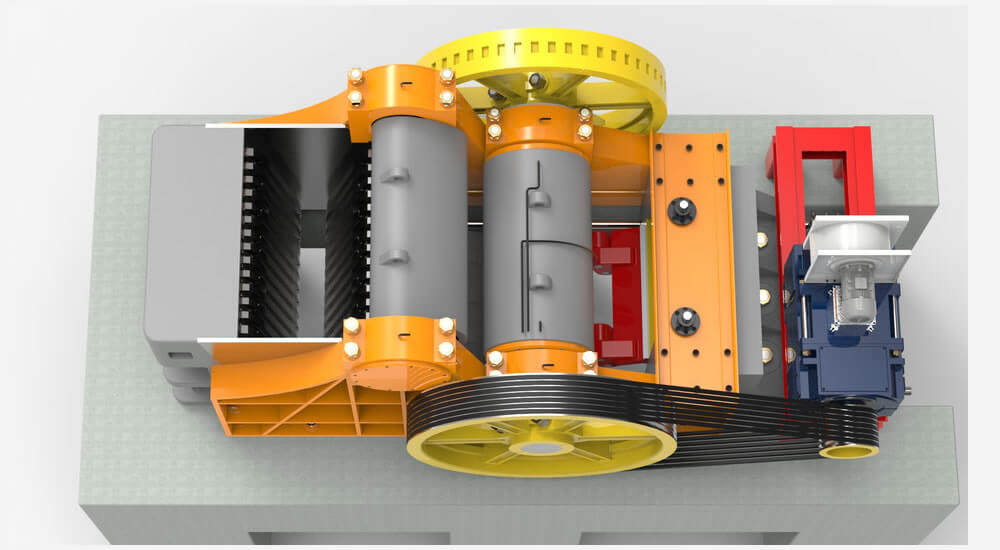

A jaw crusher basically consists of two crushing plates inclined to each other, forming a horizontal opening at their lower edges. The material is crushed between a fixed and a moving plate by back and forth pressure until the crushed product is small enough to pass through the gap between the crushing plates. Jaw crushers find a wide range of applications for brittle materials. For example, they are used for the crushing of porous copper cake.

A rotary crusher consists of a solid cone mounted on a rotating shaft and housed within a hollow body with tapered or vertically inclined sides. When the crushing surfaces approach each other, the material is crushed and the crushed products fall through the discharge opening.

Crushers are essential equipment for the reduction of material sizes in metallurgical, mechanical and other related industries. During the processing of bulk materials, various lumps and clusters can occur. This is especially true for powders and granules that “harden together” during storage. The different shapes and sizes of the material make further processing difficult. Crusher crushers gently reduce these particles to a consistent and uniform final particle size while preserving the product. They are classified as compression jaw, gyratory and cone crushers, shearing cutter mills and impact hammer crushers.

Hammer crushers

The materials are reduced to a size small enough to pass through the grid or screen openings. The size of the product can be adjusted by changing the spacing of the grid bars or the opening of the screen. The hammer crushers are characterized by high air pressure in the discharge unit of the crusher and low pressure in the area around the crusher. The shaft is close to the inner surface of the body side walls. Thus, hammer crushers also serve as high-pressure forced draft fans. This can lead to environmental pollution and product losses in the case of fine dust fractions.

The materials are reduced to a size small enough to pass through the grid or screen openings. The size of the product can be adjusted by changing the spacing of the grid bars or the opening of the screen. The hammer crushers are characterized by high air pressure in the discharge unit of the crusher and low pressure in the area around the crusher. The shaft is close to the inner surface of the body side walls. Thus, hammer crushers also serve as high-pressure forced draft fans. This can lead to environmental pollution and product losses in the case of fine dust fractions.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.