Cooling tower design

Cooling tower design is important for manufacturing a semi-closed device that cools water by evaporation as a result of contact with air.

- Home

- Our-services

- Cooling tower design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

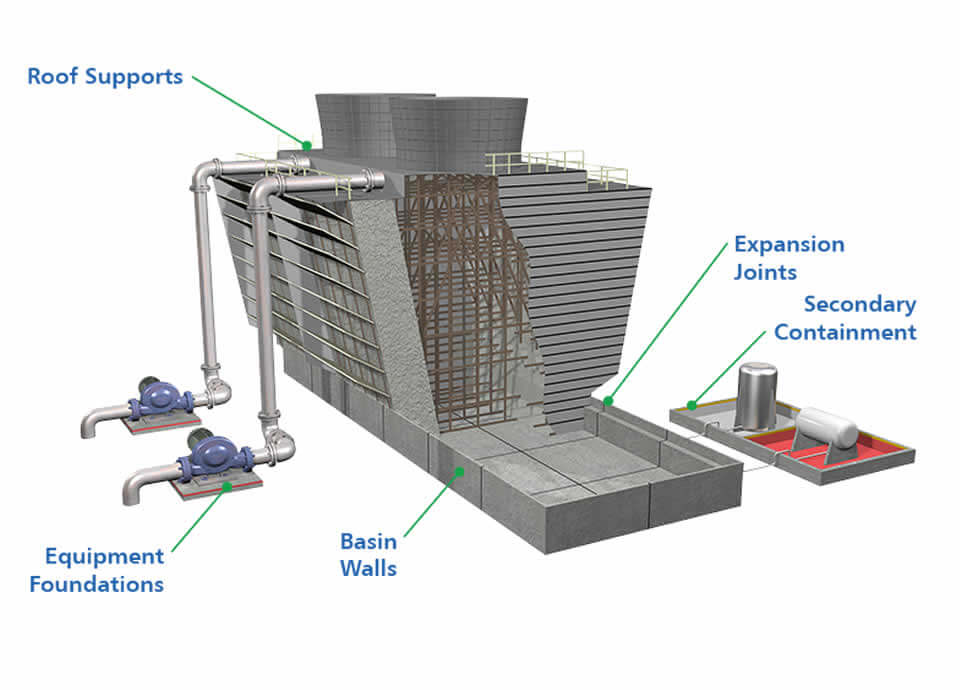

Cooling tower design

Cooling towers are wooden, steel or concrete structures with corrugated surfaces or baffles or perforated. Trays are provided inside the tower for even distribution and better atomization of the water in the tower. Hot water condenser discharge is fed to the upper tower and allowed to tickle into fine drops. Air flow Water flow from the bottom of the tower or perpendicular to its direction and exhaust cooling to the atmosphere after being effective. Air flow to prevent water particles from escaping with the air Screeners are located at the top of the tower.

Cooling towers are thermal management devices that extract waste heat from water and release it into the atmosphere, effectively cooling the water for reuse or disposal. Their main function is to achieve cooling through the evaporation process that occurs when water comes into contact with air. Such towers are of fundamental importance in sectors that require the distribution of large amounts of heat, such as power generation, chemical industry and HVAC systems. The working principle of a cooling tower is explained in the video below.

How does a cooling tower work?

Cooling towers operate on the principle of evaporative cooling. Hot water from industrial processes enters the tower, where it is distributed homogeneously over a filler material, usually made of thin plastic or wood. As the water moves downward through the filler material, it is in constant contact with a stream of air. This contact causes a certain amount of water to evaporate and the remaining water to absorb heat. As a result, the cooled water is collected at the bottom of the tower and is ready to be reused in the industrial process.

The evaporation process is considered to be the fundamental element of the cooling tower’s performance. As water evaporates, it absorbs heat from the surrounding water, thus reducing its temperature. The evaporation rate of the cooling tower depends on variables such as the surface area of the water exposed to the air, the temperature difference between the air and the water, and the air humidity. Therefore, engineers who design cooling towers optimize these parameters in order to maximize the cooling efficiency of the tower.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.