Chain conveyor design

Chain conveyor design are used in production facilities to ensure the efficient and safe transportation of materials and products throughout the production area.

- Home

- Our-services

- Chain conveyor design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

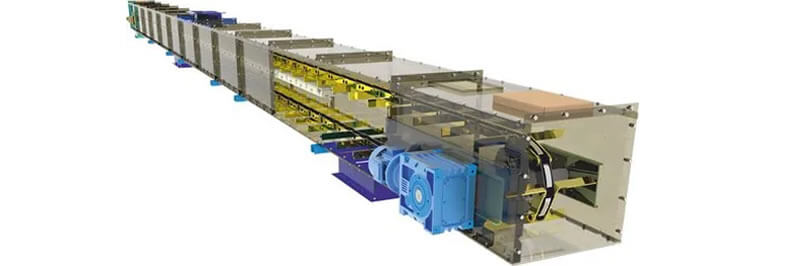

Chain conveyor design

In any industrial production facility, the optimal organization of material handling processes is of great importance. A fluid material handling system can effectively manage different fuel quantities by providing continuous supply to the boilers. One of the critical components of this system is the drag chain conveyor. A suitable drag chain conveyor system designed for specific environments is the basic element of a durable, efficient and heavy-duty material handling system.

The working principle of a chain conveyor is quite simple. It is based on the movement of the chain around the front and tension drums. During this movement, the containers mounted on the chain move the load. In roller conveyor chains, the load can be moved both from the upper working arm and from the bottom. Conveyor system design requires the expertise of expert process engineers who understand the production environment and the importance of operator safety, product protection and system efficiency.

Drag chain conveyors stand out as the most suitable solutions for dust-free environments where hot, abrasive and corrosive substances are present. These conveyors offer high efficiency in the transportation of coal, limestone, biomass, wood, derivative fuel (TDF), ash and various other bulk materials.

How to choose the right Chain Conveyor System?

Choosing a suitable chain conveyor system and material handling system requires careful consideration of various factors, and this step, if implemented, can significantly increase operational efficiency. In the decision-making process, understanding the needs and requirements, as well as carefully evaluating the variables, is of critical importance. Choosing the right conveyor system can significantly improve your profitability.

When considering chain conveyor systems for your facilities, there are various factors to consider in bulk material handling. It is recommended that you make your decision by considering the seven basic factors listed below:

Suitable for the Conveyor Environment

What are the environmental conditions in which the conveyor system will operate? The conveyor should be designed and manufactured to suit the specific conditions of the environment in which it will operate, such as temperature, dust density and the characteristics of the materials to be transported.

For example, chain conveyors are often used in harsh environments with high temperatures, abrasive effects and corrosive substances. It is extremely important to take protective measures to prevent premature wear or damage caused by harsh conditions in such conveyors.

Improving Productivity with the Right Drag Chain Conveyor Design

When choosing a conveyor system, efficiency should be a primary goal. Choosing the right drag chain conveyor system plays a critical role in maintaining operational efficiency in industrial facilities. The selected conveyor type should be capable of handling heavy loads and should be able to operate smoothly in high temperature conditions.

The designed system should be structured to optimize the transportation of bulk material and the discharge points should facilitate efficient material transfer. In addition, when choosing a drag conveyor, it is necessary to ensure that it is compatible with existing systems and processes.

Effective process management can create significant savings opportunities that significantly reduce operating costs. Some drag chain conveyor designs include multiple entry and exit points, providing a more efficient and flexible structure that improves the flow efficiency of materials. The number of chains can be varied from single-chain models to multi-chain variants depending on the customer’s specific requirements.

The design of each drag chain conveyor system should aim to optimize the system in order to maintain particle integrity. This can reduce or eliminate fuel integrity problems that can negatively impact combustion efficiency. The proper conveyor system ensures that the quality of the material is maintained throughout the process by processing the material without causing deterioration or damage.

Understanding the material properties, understanding the size, shape, density and flow characteristics of the materials to be conveyed is critical. This knowledge helps ensure that the conveyor system is suitable and will not damage the materials, and also optimizes the efficiency and performance of the system.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.