Ball mill design

Ball mill design plays an important role in all mineral processing and grinding operations, including flotation, cyanidation and amalgamation.

- Home

- Our-services

- Ball mill design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

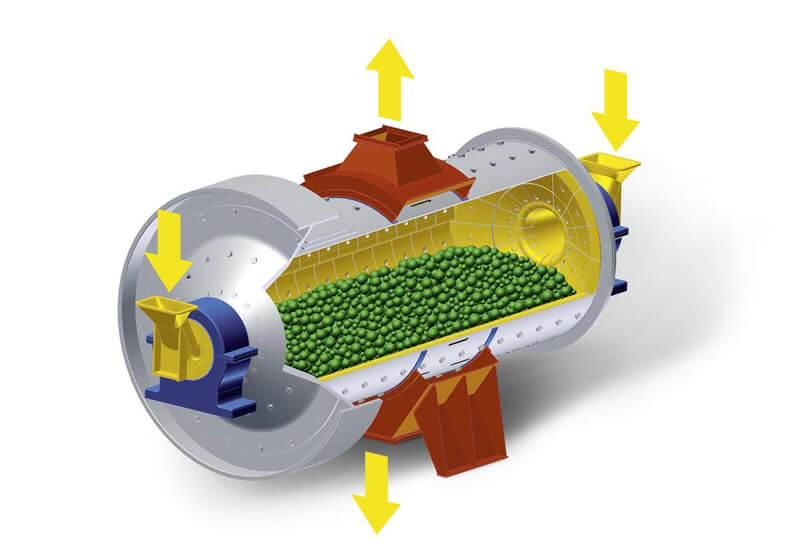

Ball mill design

In the chemical and process industries, grinding is an important step in preparing raw materials for further processing. In today’s applications, ore is reduced to a much finer size than can be achieved with crushers. Various types of fine grinding mills have been developed and used over the years, but the ball mill has become the standard due to its simplicity and low operating cost. Ball mills have the advantage of being self-contained, so operators can grind the product. The ball mill cabinet can be used equally well for wet or dry grinding. In the case of wet grinding, the particles are also dispersed in the liquid medium.

For temperature-sensitive products, ball mills can be completely enclosed to maintain the temperature of the product. Ball mills scale well, and their performance increases with increasing size. Ball mills are available in sizes from 0.1 usg laboratory scale (also known as grinding jars) to large 5,000-gallon mills. Where the finished product does not need to be uniform, a ball mill can be operated in open circuit, but where the final product must be uniform.

It is important to use the grinding mill in closed circuit, with a screen if coarse product is desired, or with a classifier if fine product is desired. In most cases, it is preferable to operate the grinding mill in closed circuit with a screen or classifier, as higher efficiency and capacity are achieved. A mill using steel rods as grinding media is often recommended, where the product must have a minimum amount of fines (rods give a more nearly uniform product).

Ball Mill Capacity vs Rod Mill Capacity

Until recently, many operators believed that one particular type of grinding mill had greater efficiency and throughput capacity than some other type. However, it is now generally accepted that the work done by any ball mill is directly related to the power input; the maximum power input to any ball or rod mill depends on the weight of the grinding load, the mill speed, and the liner design.

The apparent difference in capacity among grinding mills (listed as the same size) is due to the fact that there is no single type of mill. The method of determining the size of a mill, for example: A 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 percent more capacity than any other ball mill described as 5′ x 5′; the inside diameter of the shell is 5′ and the working diameter with the liners in place is only 4’8′.

- Grinding Mill Gears

Gears for Ball Mill drives are provided as standard at the discharge end of the mill, out of the way of the classifier return, bucket feeder or original feed. Due to the convertible type construction, the mills can be equipped with gears at the feed end. Two alternative combinations of gear drives are available: Cast Spur Gear and Pinion. These teeth are made of high grade cast iron with cast teeth made of a full pattern, not a sweep pattern. This ensures true and accurate running round rings.

The pinion is made of electrical steel with accurately formed teeth; a cut steel pinion is available. Cut Spur Gear and Pinion. The gear is made of high grade cast iron with teeth precisely machined from the blank; the pinion is a steel forging with precision machine cut teeth.

Covers the design, construction, and maintenance of boilers and water heaters. Part I focuses on rules for ensuring the safe operation of power boilers, while Part IV provides standards for heating boilers, emphasizing the safety and efficiency of hot water heating systems. See ASME Code Parts I and IV

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.