Lime Production

In lime production, high-purity limestone or dolomite is crushed after being mined in quarries and, in some cases, subjected to washing. The material is then sorted and sent to the furnace. Limestone is generally obtained from open pits opened on the surface of the earth, located close to the lime factory. However, in some special cases, subsea drillings or underground mines can also be used for this purpose.

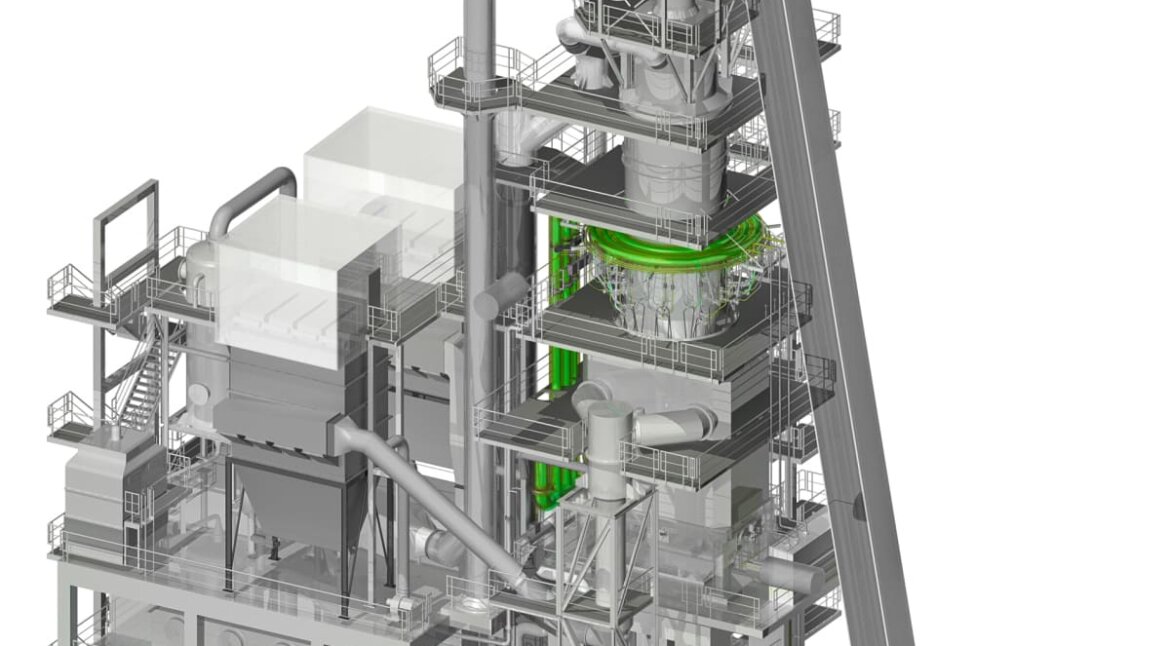

Shaft kilns from lime production (Maerz Ofenbau AG)

The main problems faced by traditional shaft kilns in lime production include ensuring a homogeneous heat release to the desired extent and smooth movement of the load along the shaft. In such systems, the fuel injected through a wall usually has a penetration of no more than 1 meter into the bed. This limitation limits the furnace diameter or width to approximately 2 meters.

However, various methods are applied to ensure homogeneous heat release in larger shaft kilns. These include mixed feeding techniques, centrally fed or lance-based solutions, fuel injections with special devices that can reach a depth of 1 meter into the kiln, and injections under arcs. In addition, methods such as the injection of air or circulating furnace gases from above the fuel also offer solutions to such problems.

In general, the design of Maerz-type shaft kilns for lime production is characterized by a relatively low fuel consumption, allowing the gases and solid material in the combustion zone to transfer heat effectively. However, this structure leaves a large portion of the sulfur in the fuel unseparated. Therefore, low-sulfur fuels should be preferred to obtain low-sulfur products. Older designs generally produced quicklime with low to medium reactivity and relatively high CaCO3 content. In contrast, modern design concepts integrate technologies that enable the production of lime with high reactivity at lower CaCO3 levels.

Before examining in detail the specific designs of shaft kilns for lime production, it is useful to take a general look at the three main processes that play an important role in the basic operation of these kilns: charging, drawing and burning.

Raw material loading process

The raw material loading process can create significant difficulties, especially when loading bulk raw materials from a single point into a shaft kiln. It is observed that large stone pieces generally tend to tip over towards the walls and smaller grains have the risk of condensation on the kiln walls. This situation causes an increase in the resistance to gas flows formed around the central axis; however, as it gets closer to the walls, this resistance level decreases and the gas flow rate passing through the central areas decreases.

As a result, a large part of the raw materials in the bed cannot be cooked sufficiently and the efficiency decreases. Different loading mechanisms have been developed to reduce such negative effects.

In the operating principles of vertical lime kilns in lime production, especially combustion in the packed bed creates significant technical problems. The main reason for this is that the gasified fuel and combustion air cannot mix effectively enough under the conditions in this structure. In order to optimize the combustion efficiency, the fuel and air mixture must be distributed homogeneously along the shaft under ideal conditions. However, regardless of the firing devices used, variations in the air-fuel ratio can occur, which complicates the lime production process.

Double-inclined shaft kilns have a more specific structure and usually consist of two sections with opposing slopes in the calcination zone. Each slope is equipped with arc gaps that facilitate the sliding of the stone. Fuel and preheated air are transferred and ignited through these gaps. Cooling air is taken from the bottom of the kiln and preheated; then it is drawn back to the combustion chambers and re-introduced into the combustion. In lime production, the system allows both gas and solid loads to exhibit a noticeably homogeneous distribution.

Therefore, energy loss is minimized and combustion performance is increased. However, the type of fuel used must be selected meticulously, as inadequate choices can lead to problems caused by structural deposits, especially fuel ash and calcium sulphate deposits. Such kilns usually produce products with high reactivity and low carbonate content.

Multi-chamber shaft kiln models are a more advanced version of double-inclined kilns. This design offers increased efficiency for calcination and usually consists of four to six inclined sections. Each of these inclined sections, arranged at opposite angles, increases the overall structural stability and performance of the system. The cooling air is preheated in the cooling chamber by the lime and then reused after being dedusted for transfer to the combustion chambers.

In addition, temperatures in the lower combustion chambers can be varied over a wide range, allowing precise control over the reactivity of the lime. Different fuel types, solid, liquid or gaseous, can be used in multi-chamber kilns, allowing the system to be used in a wide range of applications.

Contact us for Maerz kilns in lime production.