Propane Dehydrogenation

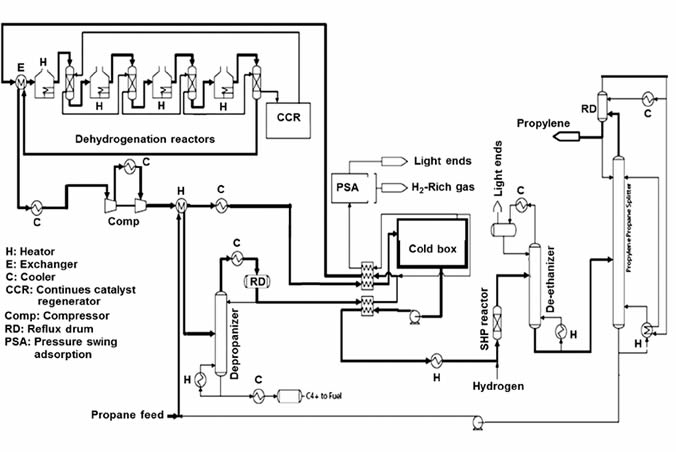

Propane dehydrogenation is a catalytic dehydrogenation process in which propanate and hydrogen is directed to a moving or fixed-bed reactor operating in a temperature range of 500-700 ° C under close pressure to atmospheric pressure.

- Home

- Fields-of-activity

- Propane Dehydrogenation

Our fields of activity

- Fertilizer (Dap)

- Sulfuric acid

- Phosphoric acid

- Ammonia plant

- Cement factory

- Sugar factory

- Feed factory

- Power plant

- Hydroelectric plant

- Process equipment

- Chemical factory

- Pharmaceutical factory

- Oil factory

- Industrial facility construction

- Structural steel fabrication

- Hydrogen Peroxide

- Propane Dehydrogenation

- Equipment design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

Propane Dehydrogenation

Propylene serves as an initial material in the synthesis of important compounds such as polypropylene, propylene oxide, acrylonitril and blutiraldehyde, one of the basic building blocks of the modern polymer and pharmaceutical industry.Recently, with the spread of Shayl gas resources, the dehydrogenation of the proponent has replaced the energy intensive and low -efficiency naphtha in the petrochemical sector. Similar to ethane dehydrogenation, two main methods for propane production are used, PDH (propane dehydrogenation) and ODH (oxidative dehydrogenation).

Although the PDH method is a process that allows a high selectivity, it exhibits a very strong endotermic reaction and has disadvantages such as stinking. On the other hand, the ODH method offers significant advantages in the presence of oxygen, lower operating temperatures, thermodynamic suitability, resistance to smell and process efficiency. However, the ODH method still faces serious difficulties such as excessive oxidation and safety risks in terms of industrial applications. For these reasons, technical obstacles that limit ODH’s more widespread use in the industry should be overcome.

In this context, the ODH method of cage oxygen is remarkable as a promising research topic. As a matter of fact, in a recent study by Chen and his colleagues, Mo-VO has been reported to be converted into propylene through the chemical loop system using Mo-VO double-function mixed oxide. The reduction process of Mo-VO mixed oxid is divided into three stages: excessive oxidation, odh and non-oxidative dehydrogenation. This is visually presented in Figure 20a and the relevant reaction mechanisms are discussed in detail.

The importance of propylene in the world

With the rapid development of the petrochemical sector in recent years, Propylene has become one of the most increasing basic raw materials. Propylene is used in the production of various chemicals, especially commercially, polypropylene, acillonitrile, propylene oxide, culmination, acrylic acid, 2-ethyl hekzanol and butanols. However, for the following reasons, despite serious problems in the production of world propylene, the demand for propylene increased by 6.5 percent in 2004, and this demand is in a continuous trend of rise due to the need for polypropylene.

For example, in Turkey, polypropylene production capacity is limited to 144 thousand tons annually. On the other hand, the demand throughout the country reached 1 million 103 thousand tons/year in 2008 and as of 2013, this figure increased to 1 million 793 thousand tons/year. A similar condition is also for acrylonitril. Turkey is one of the largest acrylic fiber manufacturers in the world. According to the objectives set within PETKİM, acrylonitril production was planned as 125 thousand tons annually in 2013, while the demand is expected to be 519 thousand tons/year levels in the same year.

In addition, considering that the acrylic acids and derivatives that are a very important input in the surface cover industry and which can be produced directly from propylene or direct propana through new technologies are still produced in Turkey, it is clear that the country’s need for propylene is clear. However, the structural problems in the propyleous supply both globally and in Turkey stand out as the most fundamental obstacle to Turkey’s high demand.

Propylene production methotds

In 1990, the number of propan dehydrogenation plants, which was only one in the world, reached 20 in 2004 and 35 in 2010. However, existing technologies work with the principle of direct endothermic dehydrogenation of the proponent, bringing some difficulties. Due to thermodynamic limitations, problems such as low balance transformation, high heat requirement and cooking in the catalyst arise. This increases the need for multi -transitional and multi -reactor systems and makes the process more complicated in order to prevent cooking.

Nevertheless, due to the rapidly increasing demand for propylene since the 2000s, interest in these technologies has increased and the number of new facilities has increased rapidly. For example, the Star process developed by UHDE GmbH was improved under the name “Oxydehydrogenation”, and instead of selected oxidative dehydrogenation, the selective burning in the second bed of a double -bed reactor was tried to increase balance efficiency.

In accordance with the polypropylene deficit in our country, Rönesans plans to start the production of polypropylene with the propane burning process in the coming years.

Our company continues engineering studies on equipment design, equipment manufacturing and by -product recycling in propane gas polypropylene production technologies. You can contact us for detailed presentation