Oil factory equipment manufacturing

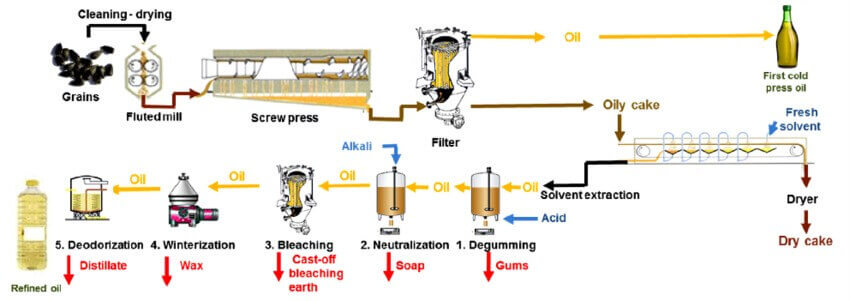

Simply put, a series of machines are used in the edible oil production process, such as cleaning machine, crushing machine, exfoliating machine, cooking machine, edible oil press machine, edible oil solvent extraction machine and edible oil refining machine.

- Home

- Fields-of-activity

- Oil factory equipment manufacturing

Our fields of activity

- Fertilizer (Dap)

- Sulfuric acid

- Phosphoric acid

- Ammonia plant

- Cement factory

- Sugar factory

- Feed factory

- Power plant

- Hydroelectric plant

- Process equipment

- Chemical factory

- Pharmaceutical factory

- Oil factory

- Industrial facility construction

- Structural steel fabrication

- Hydrogen Peroxide

- Propane Dehydrogenation

- Equipment design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

Oil Factory

Due to the specific characteristics of different oilseeds, different machines are needed for pre-treatment before pressing or solvent extraction. Tailored to Perfection. Unleash the Power of Integrated Production Solutions! Our team of experts works closely with customers to develop customized solutions that maximize economic benefits and minimize costs.

In a typical edible oil processing, the plant oil is first extracted from the seed using mechanical extraction (expeller press), followed by chemical extraction (hexane extraction). When both methods are used, less than 1% of the oil remains in the flour produced. The majority of this flour is sold for use in animal feed rations.

Components of Edible Oil

A typical vegetable oil contains many components (Figure 1). This figure shows what is in canola oil; other edible oils have different percentages of the same components. The components listed as minor make up less than 1% of canola oil, but these components play a large role in determining the stability of the oil and therefore its shelf life. Many of these minor components interact easily with oxygen in the air or with other components in the oil to oxidize and form spoilage products.

Others of these minor components are antioxidants, which prevent the components from reacting with air to form compounds associated with spoilage. The table below shows some of the minor components and their effects on oxidation. Antioxidants resist oxidation, so they help preserve the quality of the oil; prooxidants promote oxidation, so they do not help preserve the oil.

Antioxidants

Tocopherols (vitamin E)

Water

Transition metals (iron, copper)

Polar lipids

Chlorophyll

In general, it is difficult to find a process that will eliminate prooxidants without also eliminating naturally occurring antioxidants. When looking at the label of a commercially prepared oil, it is usually seen that an antioxidant has been added to the processed oil after processing to replace the compounds removed during processing.

Commercial Edible Oil Processing

The commercial edible oil processing system is often different from that used by small-scale edible oil producers. There are steps that a small-scale producer may not want or need to use with their product. Figure 2 shows a simplified diagram of commercial oilseed processing. The seed is planted and harvested like any other crop. This is followed by a cleaning process where unwanted material such as soil and other seeds are removed from the harvest. In some cases, it is preferable to shell the seed for a higher quality end product. At this point, if the seed is large, the seed is crushed or broken into smaller pieces.

These uniform pieces are then heated and conditioned before being pressed for oil. The two products of this process are the crude pressed oil and the press cake, which is the compressed dry material of the seed.The crude oil is filtered before proceeding to the final steps. However, the press cake is flaked and crushed for additional oil extraction. The flakes are ground and mixed with hexane to produce a slurry that is heated. The hexane evaporates during heating and is collected for later use. As it is heated, the ground oil releases the remaining oil, which is mixed with a small amount of hexane that does not evaporate.

It is then used for other purposes, such as meal, part of cattle feed. The mixture of oil and hexane is distilled and the hexane is removed and collected. The remaining oil and the oil from the first pressing process are bleached and deodorized using bleaching clay, leaving the oil in its final form that is packaged and sold. This entire process involves several procedures that the small-scale producer may not need or want for their final product.

Cold Pressed Oils

Small-scale pressing using expeller presses results in more oil remaining in the milled flour than is obtained from chemical processing. Typically, the oil in the milled flour from small-scale pressing is in the range of 8-15%. Commercial processing leaves less than 1% oil in the milled flour.

While extracting as much oil as possible from the seed is one goal, it is also generally an important goal to produce oil at a temperature lower than 120°F (49°C). Oil pressed at this temperature below 120°F (49°C) is called “cold-pressed” oil and is desired because of its claimed increased nutritional properties. Cold-pressed oil is also important when the oil is used directly as a motor fuel because oil pressed at a lower temperature carries lower levels of phosphorus. High levels of phosphorus in the oil can be harmful to a diesel engine and is one of the compounds with a maximum limit set in the vegetable oil standard for use as a motor fuel.

Refining

Refining oils may involve neutralizing fatty acids, removing phospholipids (a phosphorus-containing compound), and filtering the oil. Other processes may be performed to create a more stable oil for further processing. On a small scale, removing hydratable and non-hydratable phospholipids is one goal, while removing particulates by filtration is a secondary goal. Hydrators are compounds that are water-soluble. Non-hydratable compounds are insoluble in water and usually precipitate or are removed by filtration.Edible oils contain a small amount of water, so water is available to dissolve the hydratable compounds.

A simple acid wash of the crude pressed oil will cause most of the hydratable compounds to precipitate out of the water and become particles that can be settled, centrifuged, or filtered from the remaining oil. Citric acid is usually the acid of choice for this process. In one process, the oil is heated to 80°C (176°F). The oil is then stirred in a 2% citric acid, 98% oil solution. The acid consists of a solution of 30% acid and 70% water. This total mixture is held at 80°C for up to 15 minutes, then rapidly cooled, settled and separated by centrifugation. Commercial processes may include additional processing at the refining stage.

Bleaching

The oils have a characteristic color when first pressed. When available on a grocery store shelf, vegetable oils from different seeds have the same nearly colorless appearance. These oils have been bleached to remove small components that cause color. Other components, some of which are desirable, are also removed during bleaching. Bleaching removes components of the oil that increase the rate of oxidation. When oil is used at high temperatures, such as during pan-frying or deep-frying, oxidation is accelerated and characteristics such as undesirable flavors or dark colors can develop rapidly in the oil. Bleaching allows the oil to be used for a longer period of time before these undesirable characteristics develop.

To perform the bleaching process, the oil is mixed with the required amount of bleaching clay. This mixture is heated to a high temperature [90°C (194°F) to 110°C (230°F)] in the absence of oxygen (air) and stirred. Undesirable (and desirable) compounds in the oil stick to the bleaching clay particles. Filtering or centrifuging removes the clay particles and compounds adhering to the clay, resulting in an oil from which the coloring compounds have been removed (Figure 5). Bleaching clay is a type of clay mined primarily in the southern United States. It may be natural clay or it may be activated by acid washing. Activated clay attracts and retains more compounds than natural clay. Natural clay is used in bleaching certified organic oils.

Deodorizer

Oils contain a variety of components when pressed. These include vitamins, fatty acids, protein fragments, traces of pesticides, and occasionally heavy metals, as well as many other substances. Many of these either enhance or diminish the flavor and odor of the oil. Deodorization removes all of these components from the oil, leaving it tasteless and odorless; essentially the same as other deodorized oils.

This process involves evaporating the oil, which vaporizes the unwanted components and separates them from the desired material. For small-scale or local producers, this process may be undesirable for several reasons. Deodorization removes the flavors and odors that are often valued in oils, enhancing the flavor of the foods they are prepared with. Additionally, this process requires additional equipment that can be costly to purchase and maintain.