Hydrogen peroxide equipment manufacturing

The manufacture of hydrogen peroxide equipment from hydrogen and atmospheric oxygen, thus acts as a “reaction carrier” in circulating anthracinone.

- Home

- Fields-of-activity

- Hydrogen peroxide equipment manufacturing

Our fields of activity

- Fertilizer (Dap)

- Sulfuric acid

- Phosphoric acid

- Ammonia plant

- Cement factory

- Sugar factory

- Feed factory

- Power plant

- Hydroelectric plant

- Process equipment

- Chemical factory

- Pharmaceutical factory

- Oil factory

- Industrial facility construction

- Structural steel fabrication

- Hydrogen Peroxide

- Propane Dehydrogenation

- Equipment design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

Hydrogen peroxide factory equipment manufacturing

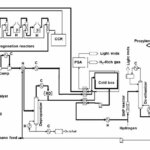

Hydrogen peroxide is produced by a process called autoxidation, where hydrogen and oxygen come together. The most important component in this process is the environment in which the reactions take place, known as the “working solution”. The process consists of three main steps. Hydrogenation, oxidation, and extraction.

Today, hydrogen peroxide is produced by a method known as the “anthraquinone process”. This method is energy intensive, requires large-scale production, and produces large amounts of carbon dioxide (CO2) as a byproduct.

Hydrogen peroxide is simply water with an oxygen atom added. Instead of H2O, the symbol for water, it is H2O2. This extra oxygen is relatively weakly bound, making it a highly reactive chemical that can oxidize other molecules around it. It is so reactive that it can be used as a weapon fuel in high concentrations, even at 35% concentrations, requiring very special handling and transportation procedures. The type used as a household disinfectant is usually single. It is 3% hydrogen peroxide and 97% water.

Hydrogen peroxide is a product that is useful, but also quite dangerous for the production phase and transportation. That is why the Hydrogen peroxide process and Hydrogen peroxide factory equipment manufacturing is a highly specialized process. Expert Equipment manufacturing Hydrogen peroxide process consultancy and equipment manufacturing. You can contact us for more information.

What is hydrogen peroxide?

Although it is usually associated with hair bleaching processes, this chemical substance has a much wider range of uses. Noted for its environmentally friendly properties, hydrogen peroxide is considered a highly effective oxidant for various sectors and industries. In this context, the basic characteristics of the product, its production processes and its potential to replace less sustainable chemical substances reveal its importance as a sustainable alternative.

First, hydrogen is added to the working solution and mixed with the reaction medium. The second step involves pumping atmospheric oxygen under pressure into the working solution, thus producing hydrogen peroxide. This is removed by adding water. This produces a 35 to 50% aqueous solution that can be treated in several stages with steam, among other things.

The working solution at the beginning of the process is the same as the final product at the end of production. Therefore, theoretically, it can be used indefinitely. However, it needs to be cleaned regularly to ensure that the reactions proceed smoothly and safely.

Hydrogen peroxide, a powerful oxidizing agent that many people associate with lightening or blonding hair, can do much more than just being a powerful bleach. Peroxide solution has antibacterial effects and eliminates odors, which is why it is used as a household cleaner and also in oxygenated water to disinfect wounds.

Peroxide is, moreover, an all-round green chemical, in high demand in a wide range of industrial sectors, from the paper industry to the food, pharmaceutical and cosmetic industries, and even electronics. It is also increasingly used in (waste) water treatment, as a reagent in chemical syntheses and even as rocket fuel.

Usage areas

- It cleans and purifies municipal and industrial wastewater without using harmful pesticides.

It disposes of paper and pulp in an efficient and environmentally friendly way and can be used in paper recycling. - It destroys bacteria in beverage packaging without leaving any residue, without affecting food quality, and provides longer shelf life even without refrigeration.

- It is used as a raw material in processes such as HPPO and HPPG in the sustainable production of globally valid materials such as Propylene Oxide and Propylene Glycol.

- It will help launch satellites in the future that can provide valuable data for sustainability on our planet through ground-based observation.

- It cleans electronic components cost-effectively without producing harmful waste.

- It helps create foams and cooling materials that save energy.

- It is used to recycle valuable materials, for example, to recover lithium from lithium-ion batteries, and in many more products.

It is a sustainable product.

Finally, hydrogen decomposes into water and oxygen. Therefore, there are no toxic or ingested products that can harm humans or the environment. This unique chemical property makes hydrogen peroxide a stable chemical that can replace other, less expensive chemicals in many areas of use.