Ammonia plant equipment manufacturing

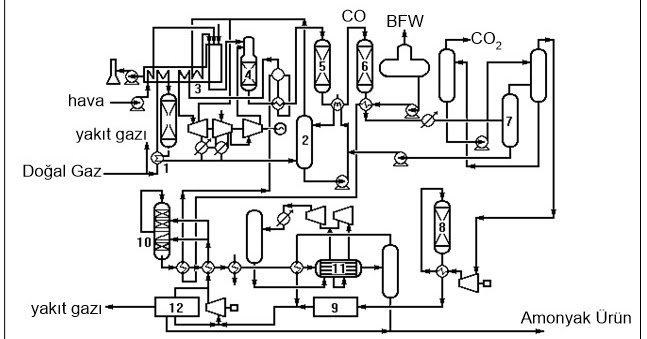

The ammonia plant equipment manufacturing primarily consists of a modern hydrogen plant, a standard nitrogen plant and high-efficiency ammonia synthesis for equipment manufacturing.

- Home

- Fields-of-activity

- Ammonia plant equipment manufacturing

Our fields of activity

- Fertilizer (Dap)

- Sulfuric acid

- Phosphoric acid

- Ammonia plant

- Cement factory

- Sugar factory

- Feed factory

- Power plant

- Hydroelectric plant

- Process equipment

- Chemical factory

- Pharmaceutical factory

- Oil factory

- Industrial facility construction

- Structural steel fabrication

- Hydrogen Peroxide

- Propane Dehydrogenation

- Equipment design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

Ammonia plant equipment manufacturing

Ammonia is critical to fertilizer production and is one of the largest volume synthetic chemicals produced in the world. This article examines the evolution of ammonia production and describes current production technologies.

Most people associate the pungent odor of ammonia (NH3) with cleaners or smelling salts. However, the use of ammonia in these two products represents only a small portion of total global ammonia production, which was approximately 176 million metric tons in 2014 (1). To appreciate where the industry and technology are today, let’s first take a look at how we got here.

Ammonia has been known for over 200 years. Joseph Priestley, an English chemist, first isolated ammonia in gaseous form in 1774. Its composition was determined by French chemist Claude Louis Berthollet in 1785. In 1898, Adolph Frank and Nikodem Caro found that N2 could be fixed with calcium carbide to form calcium cyanamide, which could then be hydrolyzed with water to form ammonia.

CaO + 3C ↔ CaC2 + CO

CaC2 + N2 ↔ CaCN2 + C

CaCN 2 + 3H 2 O ↔ CaCO 3 + 2NH 3

It was not until the early 20th century that significant amounts of ammonia were produced using the cyanamide process. Because this process required a large amount of energy, scientists focused their efforts on reducing energy requirements.

German chemist Fritz Haber performed some of the most important work in the development of the modern ammonia industry. Together with a student at the University of Karlsruhe, he synthesized ammonia in the laboratory from N 2 and H 2 .

Ammonia technology

In recent decades, chemical engineers have succeeded in creating processes that produce large quantities of ammonia at relatively low cost. Just 80 years ago, total annual production of synthesized ammonia was just over 300,000 metric tons. Thanks to breakthroughs in chemical engineering, a modern ammonia plant can produce over 750,000 metric tons per year. About 88% of the ammonia produced annually is consumed in fertilizer production. Most of the rest goes to formaldehyde production.

China produced about 32.6% of global production in 2014, while Russia, India, and the United States produced 8.1%, 7.6%, and 6.4%, respectively (1). While most global ammonia production is from the steam reforming of natural gas, significant amounts are produced by coal gasification; most gasification plants are located in China.

Modern production processes

The tremendous increase in ammonia demand from 1950 to 1980 necessitated larger, more energy-efficient plants. These decades also saw a change in design philosophy. Until then, an ammonia plant had been viewed as a collection of unrelated units, such as gas preparation, gas purification, gas compression, and ammonia synthesis. New innovations and an integrated design linked the process units together in the most efficient and effective manner.

In the mid-1960s, American Oil Co. built a 544-mt/d single-converter ammonia plant in Texas City, TX, engineered by M. W. Kellogg (MWK). The single-train design concept ( Figure 3 ) was so revolutionary that it received the Kirkpatrick Chemical Engineering Achievement Award in 1967. The plant used a four-case centrifugal compressor to compress the syngas to 152 bar, with final compression to a working pressure of 324 bar occurring in an alternating compressor. Centrifugal compressors were also implemented for the synthesis loop and cooling services, resulting in significant cost savings.

Over the past 60 years, ammonia process technology has improved significantly. Plant layouts have evolved from multiple train designs, often with different numbers of trains in the front end and the synthesis loop, to single train designs. Syngas preparation at the front end of the plant has been increased from atmospheric pressure to 30-50 barg. Capacities have increased from 100 mt/day to 3,300 mt/day on a single train.

Energy efficiencies have also improved — from ammonia consumptions of well over 60 GJ/mt in coke-based plants to 40-50 GJ/mt in the first natural gas-based plants and 30-40 GJ/mt in the first single-line plants. Modern plants have added heat recovery with steam generation at pressures as high as 125 barg in both the synthesis gas preparation section and the synthesis loop.