Cement factory equipment manufacturing

Since cement is one of the three basic materials widely used, consumed and known as the “food of the construction industry” in the construction industry, cement factory equipment manufacturing is also gaining importance.

- Home

- Fields-of-activity

- Cement factory equipment manufacturing

Our fields of activity

- Fertilizer (Dap)

- Sulfuric acid

- Phosphoric acid

- Ammonia plant

- Cement factory

- Sugar factory

- Feed factory

- Power plant

- Hydroelectric plant

- Process equipment

- Chemical factory

- Pharmaceutical factory

- Oil factory

- Industrial facility construction

- Structural steel fabrication

- Hydrogen Peroxide

- Propane Dehydrogenation

- Equipment design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

Cement factory equipment manufacturing

With the need for economic development, cement production and varieties are constantly increasing. It can be roughly divided into Portland cement, sulfate aluminum cement, aluminate cement, etc. In actual practice, as a professional EPC cement plant supplier, Arater always provides solutions according to customers’ requirements.

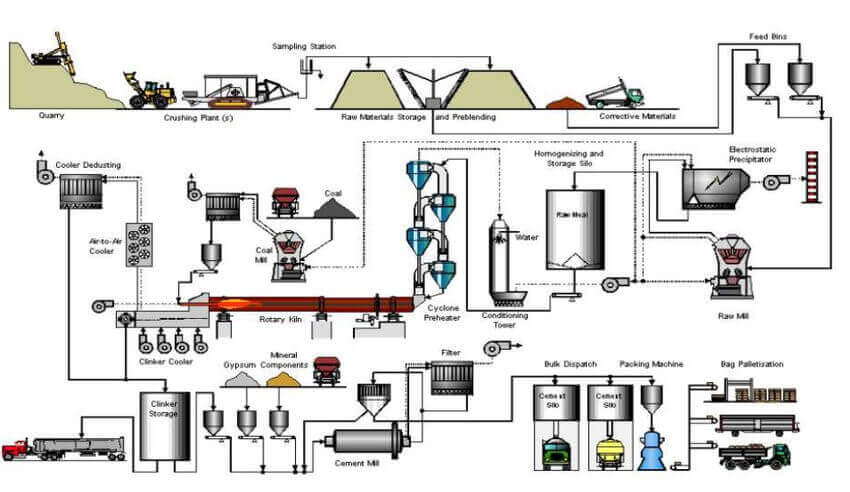

Cement Production Process

Cement requires the extraction of different minerals. Limestone (containing the mineral calcite), clay, and gypsum make up the majority. The U.S. Geological Survey notes that cement raw materials, especially limestone, are geologically widespread and (fortunately) abundant. According to the U.S. Geological Survey 2023 Cement Mineral Commodity Summary , U.S. Portland cement production in 2022 is expected to increase slightly to an estimated 92 million tons, while masonry cement production is expected to increase to an estimated 2.5 million tons.

The overall value of cement sales was approximately $14.6 billion, with an estimated 70% to 75% of sales to ready-mix concrete producers, 11% to concrete product manufacturers, 8% to 10% to contractors, and 5% to 12% to other types of customers. The Minerals Summary also notes that “cement is not recycled, but a significant amount is recycled for use as concrete construction aggregate. Cement kilns can use waste fuels, recycled cement kiln dust, and recycled raw materials such as slag and fly ash. A variety of secondary materials can be included as supplemental cementitious materials (SCMs) in blended cements and in the cement paste in concrete.”

How is cement made?

Main ingredients

Calcium

Silicon

Aluminum

Iron

Cement production is a complex process that begins with the extraction and subsequent grinding of raw materials, including limestone and clay, into a fine powder called raw milling, which is then heated to a sintering temperature of up to 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then recombined into new compounds. The result is called clinker, which are rounded nodules ranging from 1 mm to 25 mm. The clinker is ground into a fine powder in a cement mill and mixed with gypsum to form cement.

The powdered cement is then mixed with water and aggregates to form concrete, which is used in construction. The quality of the clinker depends on the composition of the raw materials, which must be closely monitored to ensure the quality of the cement. For example, excessive free lime causes undesirable effects such as volume expansion, increased setting time or decreased strength. Various laboratory and online systems can be used to ensure process control at every step of the cement production process, including clinker formation.

Cement quality

From limestone mining to crushing, blending, raw milling, kiln and beyond, elemental analysis is a critical component of driving process control, efficiency and higher quality end products. Powerful analyzers can help you better understand the composition of your raw materials and give you greater control over downstream manufacturing processes. Handheld XRF analyzers can determine material composition and contaminants or obtain geochemical data in the field or anywhere in the plant.

Laboratory X-Ray Fluorescence (XRF) systems are used by cement QC laboratories to determine major and minor oxides in clinker, cement and raw materials such as limestone, sand and bauxite.* Combination X-Ray Fluorescence (XRF) and X-Ray Diffraction (XRD) systems perform both chemical phase analysis for a more complete characterization of the sample. Clinker phase analysis ensures consistent clinker quality. Such instruments can be equipped with several XRF monochromators for the analysis of major oxides and a compact diffraction (XRD) system capable of measuring quartz in raw materials, free lime (CaO) and clinker phases, and calcite (CaCO3) in cement.

Although each cement plant varies in layout, equipment, and appearance, the general process of manufacturing Portland cement is the same: crushed limestone and sand are mixed with ground clay, shale, iron ore, fly ash, and alternative raw materials. Some manufacturers dry-grind the raw materials, while others use wet-grinding processes involving water.

Stage I: Raw Material Extraction

The raw materials needed for cement production mainly include limestone (providing the main material, CaO), clay materials (providing SiO 2 , Al 2 O 3 and a small amount of Fe 2 O 3 ), correction raw materials (to supplement some insufficient components) and auxiliary raw materials (such as mineralizer, auxiliary solvent, grinding aid), etc. Generally, limestone accounts for 80% of cement raw materials and is the main cement production material.

Cement factories are generally built near limestone quarry, so that the extracted limestone can be directly transported to the cement factory by belt conveyor or other transportation systems. If the distance between the quarry and the cement factory is too long to use conveyors, limestone needs to be transported by trucks, which means higher transportation fees and inconvenience.

The short distance between the cement factory and the quarry saves transportation fees and fuel costs, and makes the cement making process economical. In addition to limestone, there are other raw materials such as clay, fly ash, iron ore and coal used in the cement making process. The need for these raw materials in cement production is relatively small, so purchasing them from a supplier is not a problem. Before the raw materials are transported to the cement plant, they are crushed into smaller pieces by the crusher in the quarry. Compared to large pieces, smaller pieces of raw materials are easier to load and transport, and are more suitable for subsequent processing.

Stage II: Raw Material Proportioning, Mixing and Grinding

Limestone samples taken from the quarry are first sent to the laboratory of the cement plant, where they are tested and analyzed for proportioning. Proper proportioning of limestone and other raw materials is a necessary task before starting the grinding process. The proportioning of cement raw materials is not always the same, but should be determined according to the actual situation. The proportion of raw materials with different properties of cement is also different.

Generally, the proportion of the components in cement raw materials is 67-75% limestone, 10-15% clay, 0.5-1.5% iron ore and 8.5-11% coal. With the help of vertical roller mills or other types of crushers, the raw materials are blended and ground into smaller raw grinding pieces in the cement plant. In a roller mill, the rotating roller continuously rotates on the grinding table and crushes the material into fine powders and finishes the job. The raw mixture is stored in a prehomogenization pile after being ground into fine powders.

Stage III: Preheating

After the raw material is crushed by the mill, the raw material is ready to enter the preheater. Cyclone preheater is one of the basic equipment for dry process cement production, which consists of a series of vertical cyclones in several stages. Inside the cyclones, the raw material interacts with the exhaust gas from the rotary kiln and carries out suspension heat exchange with it. The suspension preheating process helps cement plants save energy and reduce environmental pollution.

Stage IV: Calcination

Calcination is the basic step of the dry process of cement making. Calcination of preheated raw material takes place in the rotary kiln of the cement plant. The rotary kiln is a huge rotary kiln in which the raw material is heated to 1450 ⁰C and converted into clinker. The high temperature in the rotary kiln initiates a series of chemical reactions between calcium and silicon dioxide compounds, and the raw material is ultimately converted into cement clinker. The heat source of the rotary kiln is the flame from the burner located at the front end of the kiln. Using natural gas or coal as fuel, the burner emits high-temperature flames to calcine the raw flour. After calcination, the cement clinker enters a cooler for cooling.

Stage V: Clinker Cooling and Final Grinding

The hot clinker discharged from the rotary kiln is cooled in the grate cooler by forced air drawn from the outside atmosphere by grate cooling fans. After cooling, the temperature of the clinker drops from 1350 – 1450⁰C to about 120⁰C. The cooled clinker is then directly transported by conveyors to the clinker silos or hoppers for storage, and then the cement grinding process is carried out. The hot air in the cooler is returned to the rotary kiln for reuse, which further saves the energy consumption of the cement plant. The cooled clinker is then fed to the cement mills for final grinding.

Nowadays, many factories prefer to use ball mills for cement grinding, because such mills have small product particle size distribution and are easy to operate. The cement ball mill is a horizontal cylinder filled with steel balls or other grinding media. Inside the cylinder, steel balls are rotated and rolled and crush the clinker into very fine powders, i.e. the product cement powder. During the grinding process, a small proportion of gypsum is added to the mixture to control the setting time of the cement.

Stage VI: Storage and Packaging

The cement product discharged from the cement grinding mills is transported to cement storage silos. It is then packed in bags or shipped in bulk quantities to customers by trucks, train wagons or ships. The most popular cement packaging machines are roto-packers, which can pack cement quickly and in large quantities.