Heat exchanger manufacturing

Heat exchanger manufacturing is produced from basic material shapes that undergo shaping, machining and welding processes to be transformed into main components.

- Home

- Our-services

- Heat exchanger manufacturing

Our manufacturing services

- Pressure vessel manufacturing

- Atmospheric tank manufacturing

- Heat exchanger manufacturing

- Conveyor belt manufacturing

- Bucket elevator manufacturing

- Storage tank manufacturing

- Chain conveyor manufacturing

- Vibrating screen manufacturing

- Tumbler screen manufacturing

- Gas scrubber tower manufacturing

- Cooling tower manufacturing

- Industrial filter manufacturing

- Ball mill manufacturing

- Crusher manufacturing

- Cooling drum manufacturing

- Drying drum manufacturing

- Reinforced concrete manufacturing

- Steel construction manufacturing

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

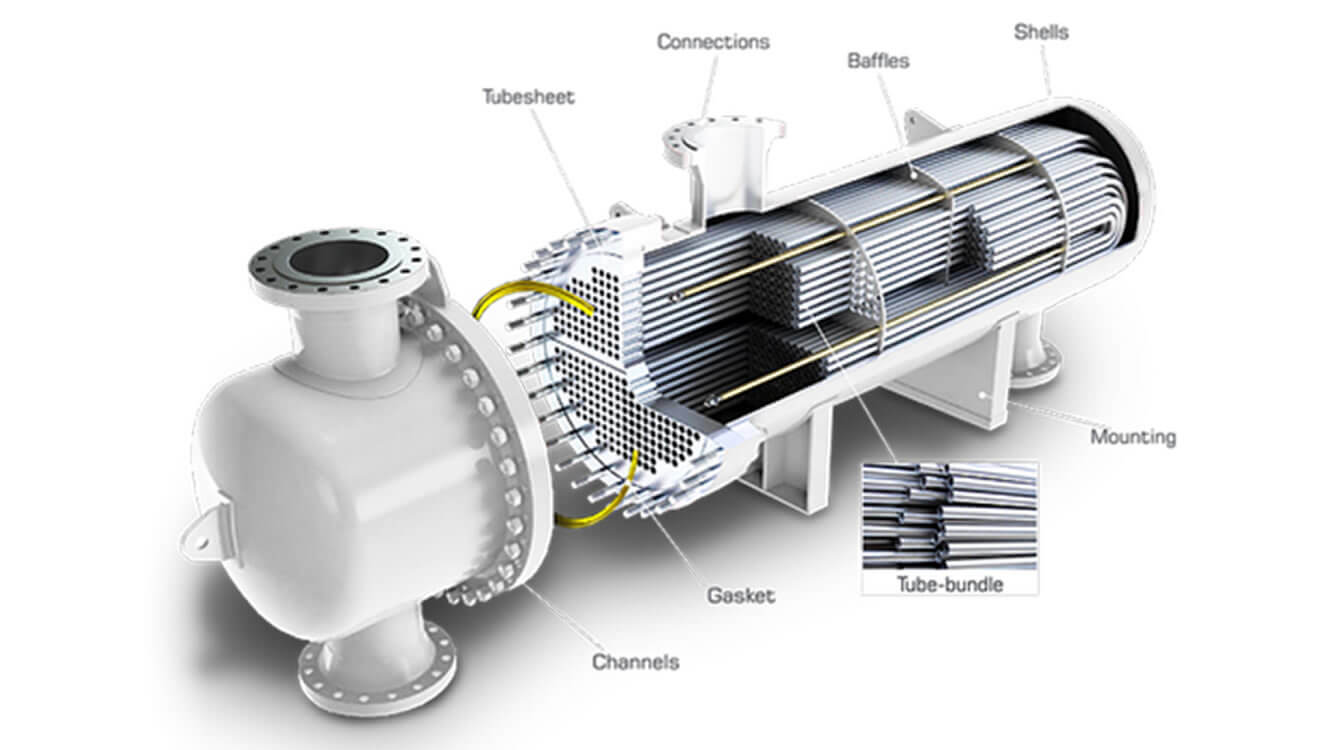

Heat exchangers

Heat exchanger manufacturing duct and shell cylinders are usually rolled and welded sheets (greater than 24 inches in diameter) or tubes (24 inches in diameter or less). Tube sheets may be sheets or forgings, depending on thickness, and are then machined and drilled. Flanges are usually hot forged rings that are then machined and drilled. Deflectors are sheet material that is cut into circles before being machined and drilled. Tubes (seamless and welded variants) come in a variety of standard diameters and sizes (thicknesses) and can be bent (into U-tubes) and cut to length as required.

Plate and tube heat exchangers

Plate and tube Heat exchanger manufacturing are complex devices and essential elements of any industrial installation for optimum thermal performance. The right experience and manufacturing methods are essential for their design and quality. Our production facility is equipped with the latest technology with dedicated production rooms for carbon and white steel, stainless steel, aluminum and special alloys to meet the needs of our customers. Heat exchangers are essential components used in various industries to transfer heat without direct contact between fluids. They efficiently manage thermal processes such as HVAC, power generation, refrigeration and chemical processing.

Areas of use of heat exchangers

Heat exchangers designed to provide heat transfer between fluids are used in various sectors. There are different types of plate, tube and special purpose heat exchangers as well as different areas of use. The main areas of use of heat exchangers, which enable engines and machines to work more efficiently in many sectors, especially in the heating and cooling of buildings, are as follows:

1-Plate heat exchangers are preferred in heating, cooling and ventilation systems.

In hot water supply

In central heating systems

In heating of pool water

In underfloor heating systems

In heating-cooling in industries with solid particle fluids such as the paper industry

In the sugar industry

In regional heating systems and

In pressure breakers.

2-It is used intensively in electricity, geothermal and heat energy recovery applications.

In geothermal heating systems

In electricity production facilities

In solar energy systems and

In heat energy recovery systems.

3-In industrial applications;

It is used in the cooling group circuit and

Waste heat recovery.

4-Its use in maritime is;

In ship cooling systems

In central cooling systems

In other cooling system applications of ships.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.