Heat exchanger design

Heat exchanger design for industrial applications based on criteria such as temperature, pressure, fluid properties, viscosity, pressure loss, thermal performance.

- Home

- Our-services

- Heat exchanger design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

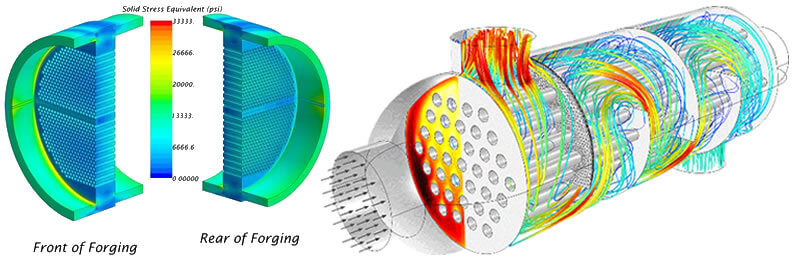

Heat exchanger design

Exchangers can be classified according to different criteria. The classification distinguishes heat exchangers (HE) in recuperators and regenerators according to the structure used. In recuperators, heat is transferred directly (immediately) between two fluids and by opposition, while in regenerators there is no sudden heat exchange between the fluids. Rather, this is done through an intermediate step involving thermal energy storage. Recuperators can be classified into direct contact and indirect contact types according to the transfer process. In indirect contact, HE, there is a wall (physical separation) between the fluids. Recuperators are called direct transfer type. In contrast, regenerators are devices in which there is intermittent heat exchange between hot and cold fluids by thermal energy storage and is released through the heat exchanger surface or matrix.

Regenerators are basically classified into rotary and fixed matrix models. Regenerators are called indirect transfer type. Heat exchangers (HE) are devices that transfer energy by heat transfer between fluids at different temperatures. Heat exchangers can be classified according to different criteria. The classification distinguishes heat exchangers (HE) in recuperators and regenerators according to the structure used. In recuperators, heat is transferred directly (immediately) between two fluids and by opposition, in regenerators there is no immediate heat exchange between the fluids.

Rather, this is done through an intermediate step involving thermal energy storage. Recuperators can be classified into direct contact and indirect contact types according to the transfer process. In indirect contact HE, there is a wall (physical separation) between the fluids. Recuperators are called direct transfer type. In contrast, regenerators are devices in which there is intermittent heat exchange between hot and cold fluids by thermal energy storage and is released through the heat exchanger surface or matrix. Regenerators are basically classified into rotary and fixed matrix models. Regenerators are called indirect transfer type.

When the mixed gas enters the system from the middle section of the washing tower, the liquid product component between the trays and the vaporized part of the product component gas simultaneously liquefies. However, impurities do not become liquid or solidify. As the gas passes through the liquid component trays, the liquid product component is fixed and thus an effective washing effect occurs. The design and production of the washing tower was carried out based on this principle.

Heat Exchanger Design Types

〉 Shell and Tube Heat Exchanger Design

〉 Double Tube or Hairpin Heat Exchanger Design

〉 Flat Plate and Fin Heat Exchangers

〉 Radiators and Solar Heat Exchangers

〉 Spiral Heat Exchangers

〉 Air Coolers, Chillers and Condensers

〉 Wet Cooling Towers

Tubular Heat Exchanger Designs

Although very simple and straightforward, the efficiency of this type of single-pass heat exchanger design is increased by the heat absorption and the primary and secondary fluids flowing in opposite directions, this is called “counterflow.” The internal heat pipe can also be a single bare tube equipped with fins to increase surface area, or a multi-tube design as shown. The efficiency can be increased by having the directional flow of the secondary fluid oppose the primary flow to increase efficiency. When both the primary and secondary fluids flow in the same direction, this is called parallel flow.

Flat Plate Heat Exchanger Designs

Flat plate heat exchangers are another common design type that offer better efficiency for their size compared to tubular designs. These types of heat exchangers provide a relatively large heat transfer surface in a small area and can also operate at higher fluid pressures. They are typically constructed by joining or “stacking” many thin metal plates together, with a small amount of space between each plate to allow the heat transfer fluid to circulate and to remove heat from the plates as it flows.

These individual plates are often joined using rubber gaskets and seals to prevent leakage and to direct the thermal fluids through alternate flow passages. Other types of flat plate heat exchangers include brazed or welded exchanger designs. The large surface area of flat plate exchangers allows for maximum contact between the two heat transfer fluids, resulting in effective and efficient heat transfer. As with the tubular design, the fluid flow of the two heat transfer fluids can be in parallel flow or counterflow, with each plate having four openings that serve as inlets and outlets.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.