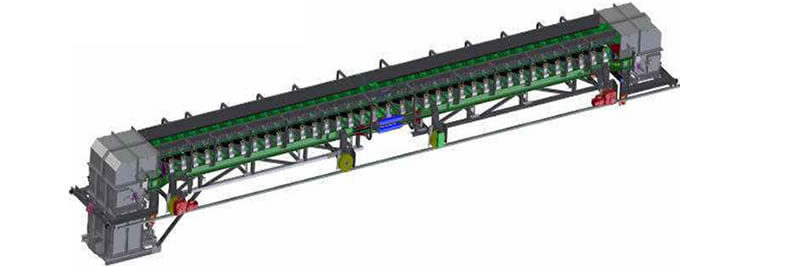

Conveyor belt design

The conveyor belt design includes two motorized pulleys on which the conveyor material is wound. The conveying medium of the belt conveyor system is one of the various conveyor systems available today and is the belt conveyor

- Home

- Our-services

- Conveyor belt design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

Conveyor belts

The conveying medium of the belt conveyor system is one of the various conveyor systems available today and is the belt conveyor. In order to work efficiently and perform the activities required by the belts, each belt conveyor system must have different modules. Depending on the weight, speed required, and flow of items in the conveyor system, various jobs can vary. The belt conveyor system consists of two or more pulleys (also known as drums) connected by an endless loop of transport vehicles (conveyor belts) that rotate around them and pull the items it carries. One or more of the pulleys to be driven will move the belt and the material on the belt forward and through the system.

Conveyor belt types

- Belt conveyor with roller bed

The surface of the roller bed conveyor belt consists of a series of rollers that are suitable for the weight and speed required by the product. The number of rollers to be used is determined by the length of the roller bed conveyor belt. Roller bed conveyor belts are used when materials are loaded by gravity. They are an excellent choice for situations where items need to be transported over long distances, as they aim to reduce friction.

- Flat belt conveyor

Although very simple and straightforward, the efficiency of this type of single-pass heat exchanger design can be increased by having the secondary fluid flow in the opposite direction to the primary fluid flow to increase heat absorption and efficiency. When both the primary and secondary fluids flow in the same direction, this is called parallel flow. When the primary and secondary fluids flow in the opposite direction, this is called “counterflow.” Additionally, the internal heat pipe can be a single bare tube equipped with fins to increase surface area, or a multi-tube design as shown.

- Modular belt conveyor

A modular belt conveyor consists of interlocking rigid plastic parts with easily removable and replaceable sections. Modular belt conveyors are easy to clean by design and the material is resistant to sharp and abrasive materials. Modular belt conveyors are available in a variety of designs and use a single belt to transport goods around curves, in straight lines, up slopes and down slopes.

- Inclined belt conveyor

Products on an inclined belt conveyor are held in place by a rough, uneven surface that prevents them from slipping or falling back. The underside of the belt is silky, allowing it to slide smoothly over the bed. Modular belt and timing belt conveyors can be used for this. Depending on the material to be conveyed, wedges can be added to further prevent slipping.

- Filter belt conveyor

Unlike traditional belt conveyors, Filter belt conveyors allow elements to pass through so that excess liquid can drain from the components or toxins and contaminants can be filtered out. Filter belt conveyors are designed with lateral grooves and holes in the center of the belt to allow liquids and fluids to escape. To prevent liquids from seeping into the belt fabric, drain holes are placed in a fabric-free area in the center of the belt, either belted or sealed. Filter belt conveyors, like sidewall conveyor belts, may have sidewalls to prevent liquids and fluids from spilling over the sides of the belt. They are constructed of heated polyester, polypropylene, polyolefin or stainless steel mesh for dewatering applications.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.