Storage tank design

Storage tank design is critical to the manufacture of containers that hold liquids, pressurized gases, or media used for short- or long-term hot or cold storage.

- Home

- Our-services

- Storage tank design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

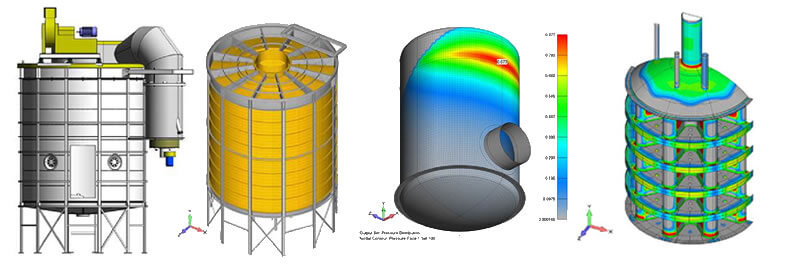

Storage tank design

Storage tanks are containers that store various substances such as liquids, compressed gases or thermal energy for short or long periods of time. These tanks, which contain organic and inorganic liquids and vapors, are widely used in many industries. They are usually designed and manufactured according to the API-650 specifications of the American Petroleum Institute. Our teams, which specialize in the design of storage tanks, LPG cylinders and pressure vessels, have extensive project experience to provide a wide range of Surge Analysis and Finite Element Analysis services. API Storage Tank Design Services is one of the most important services offered by Universal Engineering.

Storage tanks containing organic liquids, non-organic liquids, vapors can be found in many industries. The design of storage tanks, LPG tanks and pressure vessels is our strength and our teams have extensive project experience and experience to provide a wide range of Surge Analysis services. Finite element analysis. API Storage Tank Design Services is one of the highlights of Universal Engineering services. These tanks can range in size from 2 to 60 m or more. They are often installed inside containment basins to control spills in the event of a tank explosion. Industries in which storage tanks may be found include: petroleum production and refining, petrochemical and chemical manufacturing, bulk storage and transfer operations, and other industries that consume or produce liquids and vapors.

Types of storage tanks:

Industrial fuel storage tanks, also known as petroleum tanks, are used to store a variety of liquids. These tanks can store organic and inorganic liquids, as well as vapors and other flammable liquids. They come in a variety of designs and sizes and are specifically designed for different types of fuels, vapors, and industrial liquids.

〉 Industrial fuel storage tanks

〉 Industrial chemical storage tanks

〉 Industrial oil storage tanks

〉 Industrial hot water storage tanks

〉 Industrial water and liquid storage tanks

〉 Industrial gas storage tanks

〉 Horizontal tanks

〉 Pressure tanks

〉 LNG (Liquefied Natural Gas) tanks

The first four types of tanks are cylindrical and have a perpendicular axis to the ground. Almost all of these tanks are above ground. Horizontal tanks can be used above ground or below ground. Pressure tanks are usually oriented horizontally and are spherical in shape to maintain structural integrity at high pressures. They are located above ground. Variable vapor space tanks can be cylindrical or spherical in shape.

Types of Industrial Fuel Storage Tanks

Fuel storage tanks fall into two main categories.

Above and Underground Tanks:

Above Ground Fuel Tanks Above ground fuel tanks are a popular option due to their lower maintenance requirements and upfront costs in the long term. These tanks are more economical to install than underground tanks because they do not require complex piping and do not require deep excavation or paving. Above ground tanks make maintenance easier. Access is relatively easy to detect and repair leaks. For this reason, they are often preferred for storing fuels and chemicals.

Underground Storage Tanks:

Underground storage tanks are systems where at least 10% of the stored volume is buried underground. These types of tanks are used to store hazardous materials or fuels and must be registered with the EPA. They are suitable for those looking to create more space or increase property value. They can be placed out of sight under lawns or driveways. They are generally considered safer because the risk of explosion is low. However, the risk of leaks and contamination may increase due to limited opportunities for regular inspections.

Industrial Chemical Storage Tanks

Industrial chemical storage tanks are used to safely store fertilizer, propane, liquefied natural gas, petroleum products (gasoline and diesel), crude oil and other chemicals. These tanks are designed in different shapes and sizes to meet the various needs of the industry. They also play a central role in the mixing, processing, static storage and transportation of finished chemical products and raw materials.

Types of Industrial Chemical Storage Tanks

There are three main types of industrial chemical storage tanks:

• Stainless steel tanks

• Polyethylene tanks

• Fiberglass (FRP) tanks

Stainless steel storage tanks are preferred for their durability and efficiency; however, they are not compatible with many types of acids and are generally a higher cost option.

Fiberglass tanks are suitable for certain applications. However, they have disadvantages such as having seams that can leak, requiring more maintenance and being open to human error due to being manufactured by hand. They are also sensitive to certain chemicals that can corrode glass, such as hydrofluorosilicic acid.

Polyethylene storage tanks come in two main types: cross-linked and linear polyethylene. These materials make for the most versatile industrial storage tanks available on the market.

Industrial Oil Storage Tanks

Oil storage tanks can be defined as special reservoirs and containers used at different stages of the transformation of oil into various petroleum products or for temporary storage before consumption. The material and structural properties of these industrial oil storage tanks are determined according to their areas of use and the safety, environmental and legal requirements of other types of storage media.

Different sizes, shapes, materials and types of storage tanks are used from the initial production stage of crude oil to the distribution and refining of various petroleum products.

Today’s modern industrial oil storage tanks are manufactured from materials such as carbon steel, stainless steel, reinforced concrete and plastic. In addition, underground facilities are also created by carving rock salt beds that provide impermeability for the purpose of storing oil. Over time, various types of such oil storage tanks have been developed.

Industrial Hot Water Storage Tanks

Industrial hot water storage tanks offer a structure manufactured with the American Society of Mechanical Engineers (ASME) certification for industrial applications that require a continuous supply of hot water. Heating water during periods of low demand allows for quick access during periods of high demand, so that energy can be used efficiently.

Water has a high specific heat capacity, making it an effective heat storage medium. This capacity allows water to store more energy per unit mass than other substances. In addition, water is a low-cost and non-toxic substance.

Highly insulated industrial hot water storage tanks reduce fuel costs by being able to retain stored heat for days. These tanks may include various components such as internal oil or gas burner systems and electric immersion heaters. Certain types of hot water tanks use external heat exchangers, similar to central heating systems. Alternatively, these types of tanks can also process heated water from another energy source.

Su, yüksek özgül ısı kapasitesine sahiptir ve bu özelliği onu etkili bir ısı depolama aracı yapar. Bu kapasite, suyun diğer maddelere kıyasla birim kütle başına daha fazla enerji depolamasına olanak tanır. Ek olarak, su maliyeti düşük ve toksik olmayan bir maddedir.

Son derece iyi yalıtılmış endüstriyel sıcak su depolama tankları, depolanan ısıyı günlerce muhafaza edebilme kapasitesiyle yakıt maliyetlerini düşürür. Bu tanklar, dahili yağ veya gaz brülör sistemleri ile elektrikli daldırma ısıtıcıları gibi farklı komponentleri içerebilir. Belirli türdeki sıcak su tankları ise merkezi ısıtma sistemlerine benzer şekilde harici ısı eşanjörleri kullanır. Alternatif olarak, bu tank türleri başka bir enerji kaynağından ısıtılmış suyu da kullanarak işleyebilir.

Industrial Water and Liquid Storage Tanks

Tanks used for storing water and various liquids have different features for specific applications and are available in various types. These tanks are widely used for substances such as kerosene, Jet A fuel, diesel, gasoline and waste oil, as well as underground burial and pressurized applications.

Types of Water and Liquid Storage Tanks

Onion Tanks:

Onion tanks, which offer fast water storage solutions in emergency situations, attract attention with their self-rising feature and easily accessible connection parts. These portable and quickly installed tanks are ideal for extraordinary situations.

Pillow (Bladder) Tanks:

Known for their foldable structure, these tanks are effective and reusable alternatives for temporary storage needs.

Polyethylene (Poly) Tanks:

Poly tanks, which have a wide range of uses in domestic areas, are suitable for various purposes such as rainwater collection and drinking water storage. They offer a wide selection with different types such as wastewater tanks, mobile tanks, and above-ground tanks.

Fiberglass Tanks:

Known for their durability and non-corrosive properties, fiberglass tanks are resistant to high temperatures and are designed with various coatings to suit liquid storage needs.

Welded Steel Tanks:

Offering a reliable option for long-term storage, welded steel tanks can be manufactured in various shapes and sizes to suit different types of applications.

Corrugated Steel Tanks:

Corrugated steel tanks, which are preferred for their versatility, durability and economy, are manufactured from galvanized corrugated steel. They can be used in many areas such as rainwater collection, industrial process water or fire extinguishing and can be customized according to projects. They meet various needs with the long life they provide.

Industrial Plastic Storage Tanks

Water storage is vital for homes, residences, industry and commerce. Plastic water storage tanks stand out among traditional solutions to meet this need. Lightweight and highly durable, plastic tanks take up less space than cement and concrete tanks. In addition, they are more useful than traditional storage alternatives thanks to their flexible structures. These superior features have made plastic water tanks a preferred option.

Various materials are used in the production of plastic water storage tanks. These include materials such as linear low-density polyethylene, fiberglass and polypropylene.

When it comes to their applications, plastic water storage tanks are widely used in many areas such as food processing, wastewater management, chemical production, agriculture and irrigation. These tanks are designed to accommodate different types of liquids and their storage capacities range from 1.5 to 1.9 specific gravity. The plastic material used usually allows easy monitoring of the liquid level.

Plastic storage tanks are widely used for storing various liquids such as salt water, waste vegetable oils, soaps, cleaning products, industrial chemicals, pesticides, diesel exhaust fluid (DEF), liquid fertilizers, drinking water and non-potable water.

Industrial Gas Storage Tanks

Most materials are gaseous under ambient pressure and temperature conditions, and are usually supplied in compressed gas form. These gases are compressed by a compressor through piping systems into pressurized containers—such as cylinder trailers, gas cylinders, or gas canisters—for storage. Gas cylinders are the most commonly used containers for gas storage, and a large volume of cylinder production occurs in “cylinder filling” facilities.

However, not all industrial gases are supplied in the gas phase. Some gases are vaporous and can only be vaporized under constant pressure, so they can be supplied in liquid form in suitable containers. This phase change makes these gases useful in refrigeration applications. Common industrial gases with this property include sulfur dioxide, butane, propane, and ammonia.

Gas stations

Important industrial gases are usually produced in bulk and delivered to customers by pipeline, but they can also be packaged and shipped. While the majority of gases are sold in gas cylinders, some can be delivered in bulk liquid form by truck or container in suitable containers. Initially, the industry supplied gas via cylinders without the need for local gas production. However, for large-scale consumers such as petrochemical refineries or steelmaking plants, a large gas production facility can be built close to such plants to avoid the use of large quantities of cylinders; such structures are called “on-site” facilities.

Horizontal storage tank design

Horizontal tanks are constructed for both above- and below-ground service. Horizontal tanks are usually constructed of steel, fiberglass-lined steel, or fiberglass-reinforced polyester. Horizontal tanks are usually small storage tanks. Horizontal tanks are constructed so that the length of the tank is not more than six times its diameter to ensure structural integrity. Horizontal tanks are usually equipped with pressure-vacuum vents, gauge covers, and sample wells, and manholes to provide access to the tanks. In addition, underground tanks may be cathodically protected to prevent corrosion of the tank shell. Cathodic protection is accomplished by installing sacrificial anodes in the tank connected to a pressurized current system or by using galvanic anodes in the tank. However, internal cathodic protection is no longer widely used in the petroleum industry because of the corrosion inhibitors now found in most refined petroleum products.

LNG Storage Tank design

A liquefied natural gas storage tank or LNG storage tank is a special type of storage tank used for the storage of Liquefied Natural Gas. LNG storage tanks can be found underground, above ground, or on LNG carriers. A common feature of LNG storage tanks is that they can store LNG at very low temperatures, such as -162°C. LNG storage tanks consist of a double container with LNG on the inside and insulation on the outside. The most common type of tank is the full containment tank. The tanks are roughly 55 m (180 ft) high and 75 m in diameter. If LNG vapor is not released in LNG storage tanks, the pressure and temperature inside the tank will continue to increase. LNG is a cryogen and is kept in a liquid state at very low temperatures. If the pressure is kept constant by allowing the boiling gas to escape from the tank, the temperature inside the tank will remain constant. This is called auto-cooling.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.