Drying drum design

The drying drum has been a part of the heat treatment industry for over a century and has earned its reputation as a workhorse of drying drum design.

- Home

- Our-services

- Drying drum design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

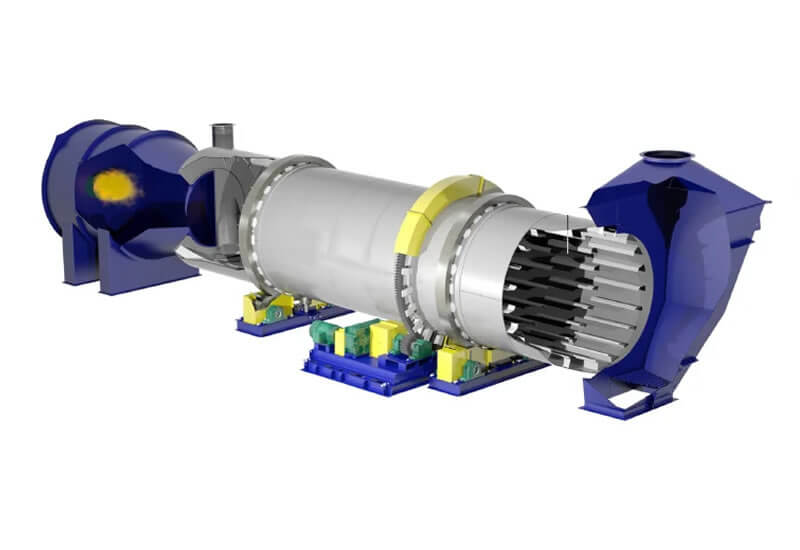

Drying drum design

Industrial Drying drum design systems have become a staple in nearly every industry that requires the drying of bulk solids, including agriculture, chemical and mineral processing, among others. Rotary dryers are often chosen for their high-capacity processing capacity, heavy-duty construction and tolerance for changes in feedstock. These qualities allow rotary dryers to produce consistent, uniform results in a consistent and efficient manner. Whether processing fertilizers, catalysts, additives or other chemical compounds, manufacturers rely on their production equipment to keep their operations running every day.

In Drying Drum Design Rotary drums are widely used in the chemical processing industry. They are a leading piece of equipment, with their flexibility allowing them to serve in a variety of capacities, including dryers, ovens, granulators, coating drums and coolers, among other roles. One aspect that contributes significantly to maximizing the efficiency of heat transfer in a rotary dryer is the engineering and implementation of what is called flight.

Lifting wings

Vanes, or material lifters, are fin-like structures attached to the inside of a rotating drum. As shown in the diagram below, these flights take material from the bed and introduce it into the hot gas stream as the drum rotates, creating a “curtain” of material. This maximizes heat transfer between the process gas and the material to promote maximum drying efficiency. Depending on the manufacturer, vanes are typically available in many forms, including straight, single-twist, double-twist, and radial designs. These designs can be further customized to enhance the design for a given scenario. Vanes can be made from any metal (carbon steel, AR steel, stainless steel, etc.) depending on the characteristics of the material being processed.

Unfortunately, the central role that rotary drums play in chemical processing plants means that one problem or failure has the potential to bring the entire operation to a standstill, requiring manufacturers and plant managers to carefully consider the design of all plant rotary equipment. Below is a list of considerations to keep in mind when designing any type of rotary drum for use in chemical processing plants.

Requirements for rotary drums in chemical processing

The most critical, yet sometimes overlooked, aspect of the design of a rotary drum (or any chemical processing equipment) is that the equipment meets three basic criteria:

- ✓ Efficient and capable

It may sound obvious, but chemical processing equipment needs to be able to accomplish its intended purpose and do so as efficiently as possible. The job of chemical manufacturers is to consistently meet exact specifications. Any equipment that fails to achieve this only adds to operating and maintenance costs in the form of inefficiency, product loss, downtime, and more. While some industries may use a one-size-fits-all approach, the chemical industry is not one of them. The need to consistently meet exact specifications and the use of high-value materials requires efficiency at every step. Therefore, rotary drum equipment must be designed to the exact specifications of the material being processed, along with the production goals.

- ✓ Reliable

Similarly, chemical manufacturers should choose equipment they can rely on, whether it’s seasonal or 365 days a year. The equipment should be designed to meet production schedules with minimal downtime and maintenance costs. For example, some fertilizer manufacturers may run nonstop for an entire season and want their granulator drums and rotary dryers to operate reliably throughout the season and reach their allotted maintenance window.

- ✓ Safe

It goes without saying that safety should be a top priority in the equipment design process. Rotary drums are generally mechanically simple, but as with any process equipment, the potential for problems is always present. Original equipment manufacturers (OEMs) should take appropriate safety precautions, such as shielding and sealing, as well as consider potential reactions that may occur during processing.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.