Reinforced concrete structures design

Since concrete is arguably the most widely used construction material in the world, reinforced concrete structure design is also of vital importance.

- Home

- Our-services

- Reinforced concrete design

Our design services

- Pressure vessel design

- Atmospheric tank design

- Heat exchanger design

- Conveyor belt design

- Bucket elevator design

- Storage tank design

- Chain conveyor design

- Vibrating screen design

- Tumbler screen design

- Gas scrubber tower design

- Cooling tower design

- Industrial filter design

- Ball mill design

- Crusher design

- Cooling drum design

- Drying drum design

- Steel structure design

- Reinforced concrete structures design

Promotional brochure

Download our catalogue to see specific data about the service we provide and how we work.

Stay in touch!

Please feel free to contact us. We will get back to you within 1-2 business days. Or call us now.

Reinforced concrete structures design

Only about a hundred years have passed since the use of reinforced concrete in structural engineering. Compared to the ancient earth and wooden structures used by early humans, structures made of stone or brick emerged in the early periods of ancient civilizations, and steel and other metal structures were developed with the Industrial Revolution.

Reinforced concrete structures are the youngest of these types of structures. However, the performance and production techniques of reinforced concrete are constantly being improved, structural configurations and construction processes are becoming more diverse, and areas of use are expanding. Today, reinforced concrete structures have become one of the most important elements of structural engineering, especially in many countries such as China.

Currently, the engineering fields where reinforced concrete structures are widely used are:

– Civil engineering: It is used in structures such as various civil and public buildings, single or multi-storey industrial structures, high and long-span buildings.

– Bridge and communication engineering: It is involved in structures such as decks, beams, arches and truss superstructures, abutments, piers, foundations, slope protection elements, retaining walls, highway pavements and railway sleepers.

– Hydraulic and port engineering: It covers projects such as dams, hydroelectric power plants, coastal structures, offshore platforms, ponds and pipelines and aqueducts.

– Underground engineering: Used in areas such as tunnels, railways, mines, caissons, piles and heavy equipment foundations, as well as military defense structures.

– Specialized engineering: Used in structures such as television towers, transmission poles, viaducts, silos, chimneys, and airport sidewalks and parking areas.

Reinforced concrete structures also include machine structures such as reactor vessels, and are used in areas where traditionally only steel structures were used, such as nuclear power plants, hydraulic presses, shipyards and lathes.

When plain concrete is evaluated as an independent construction material, its value is seen to be quite limited. The main reason for this limitation is the brittle nature of concrete and its relatively low tensile strength compared to its compressive strength. The compressive strength value of a typical concrete is usually around 30 N/mm². However, it is expected that this concrete will crack at a stress level of approximately 2.5-3.5 N/mm² when it is required to work under tensile loading.

As a result, steel reinforcement is used to resist the tensile forces occurring in the concrete section. The application of steel reinforcement also allows for ductile failures to occur, which are safer than sudden and explosive failures.

It is produced from a mixture of cement, sand, gravel and water through a process known as hydration reaction. Fresh concrete can be poured into different molds and forms to achieve the desired shape. This is one of the reasons why it is an attractive building material. In its hardened state, concrete is very good in compression but weak in tension. To increase this natural weakness of concrete in tension, steel reinforcement is often added to counteract the tensile stresses.

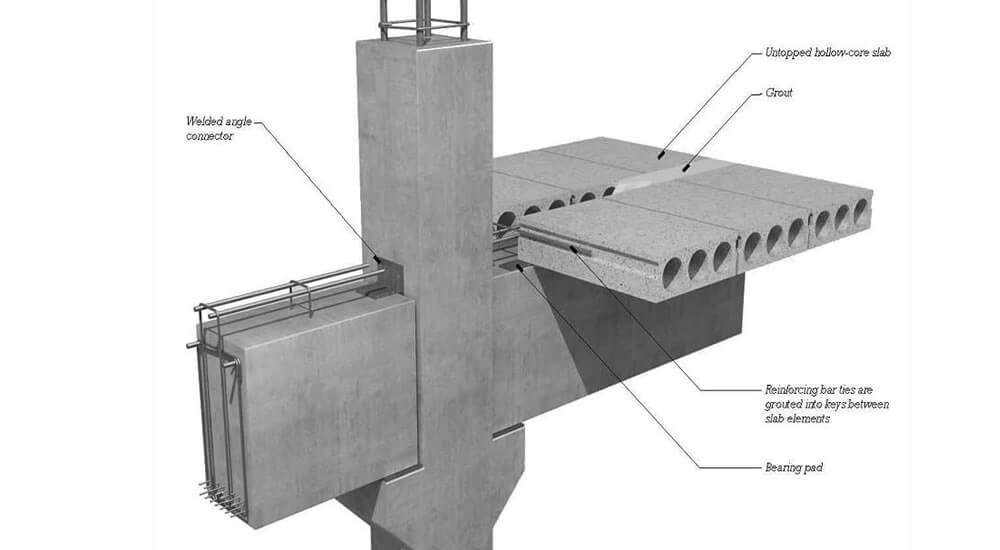

Any structure consisting of steel reinforcement embedded in concrete to form a load-bearing composite is known as a reinforced concrete structure. The process of determining the concrete element dimensions and steel area required to ensure that a structure performs well under load is known as reinforced concrete design.

Based on these assumptions, all tensile stresses in a structure are transferred to the reinforcement during design. These tensile stresses are transferred by the bond between the concrete and the reinforcement. The assumption of perfect bond requires that the strain in the reinforcement be the same as the strain in the adjacent concrete (compatibility of strains). In addition, the coefficients of thermal expansion for steel and concrete are of the order of 10 x 10-6/°C and 7-12 x 10-6/°C, respectively. These values are close enough that bond problems rarely arise due to differential expansion between the two materials over normal temperature ranges.

Steel reinforcement

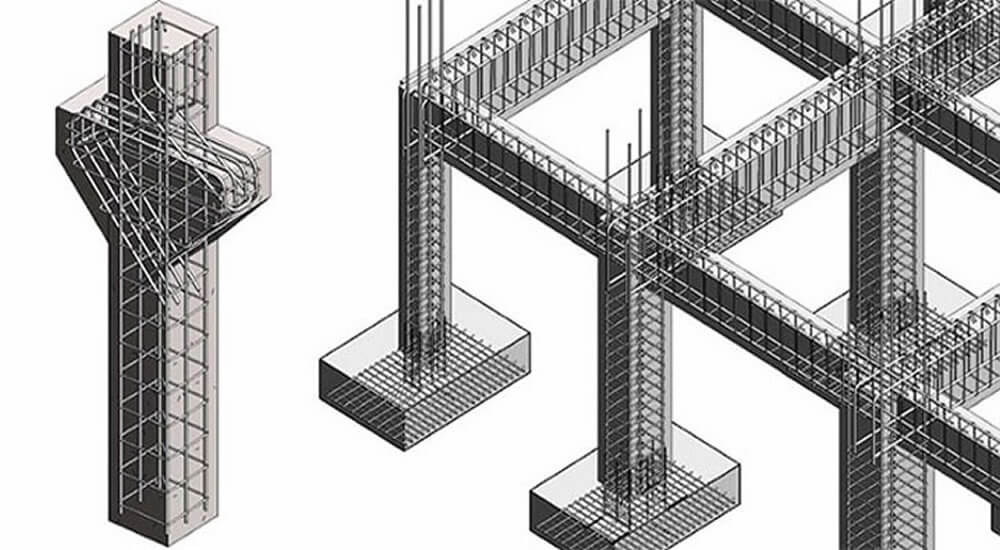

The most commonly used reinforcement material in Europe and the UK is high strength steel with a characteristic yield strength, which typically offers a yield strength of 500 N/mm². Although these steels appear to be circular in cross-section, they have a deformed surface between the steel and the concrete to increase their mechanical bond. Rebars are supplied in standard diameters, ranging from 6, 8, 10, 12, 16, 20, 25, 32 and 40 mm.

Each steel bar can be shaped and bent to form reinforcement cages. This process is still a labor-intensive manual process. When combined with the required curing time for the concrete, this method can result in longer construction times compared to a similar structure built using structural steel, for example. However, as discussed in our previous lessons, reinforced concrete structures can offer several other advantages to offset the slower construction times.

Frequently asked questions

Industrial equipment is the backbone of a variety of industries, increasing operational efficiency and productivity while supporting quality control. But to do this, such equipment must be reliable, efficient and durable. It all starts with the assembly of high-quality parts.

Experience is key when choosing an equipment provider. Be wary of startups that promise big results but lack the insight and scalability that comes with experience. Our company has been in the industry for over 25 years with 100% equity.

Our company has experience in sulfuric acid plant equipment, phosphoric acid plant equipment, fertilizer factory equipment, ammonia factory equipment, cement factory equipment, sugar factory equipment, oil factory equipment, thermal power plant equipment manufacturing, hydroelectric power plant equipment manufacturing, pharmaceutical factory equipment manufacturing, feed factory equipment manufacturing, chemical factory equipment manufacturing, all types of industrial facility construction and all types of structural steel manufacturing, and we adapt more environmentally friendly and sustainable technologies to our engineering solutions.

In addition to Carbon steel and Stainless steel equipment, we design and manufacture process equipment with different metallurgies such as Hastelloy, Alloy20 and Incoloy.

Although CNC machining is a precision manufacturing method, our local and international quality control procedures ensure that your finished part is to specification and adheres to specified tolerances.

Delivery time varies depending on the type and quantity of equipment or machinery, and usually ranges from weeks to months.